- New build

- Posted

Net result: Bristol passive house turns energy bills into net profits

A ground-breaking new passive house in Bristol makes superb use of an urban plot to create a bright and spacious home built from ecological materials that — thanks to its huge solar roof and Tesla battery pack — produces more energy than it uses, making it one of the first UK projects to meet the passive house ‘plus’ standard, while also blitzing the RIBA 2030 Climate Challenge’s targets for operational energy.

Click here for project specs and suppliers

Building: 153 m2 detached timber frame house

Location: Bristol

Standard: Certified passive house plus

ENERGY BILL £162 PER YEAR PROFIT (see ‘In detail’ for more)

As we get older, many of us feel the cold more, especially if disability leaves us inactive. So if you are planning a home that you’ll be able to live in comfortably for a very long time, it makes sense to build a passive house.

However when Bristol residents Janet and Bernard decided to make their new home a passive house, their thoughts were very much turned outwards: to future generations, and to doing the right thing by the planet.

Janet and Bernard were living in an ideal location for their retirement, in a busy neighbourhood centre on the fringe of Bristol. Shops, libraries, doctors, buses – everything was on the doorstep. But now that their children had grown and started families of their own, their family home was too big.

And they knew from personal experience that their house, product of more than 200 years of extension and alteration, was completely unsuitable for anyone with disabilities. Janet’s mother had become infirm and lost mobility as she aged, but try as they might, they could not accommodate her: “All the doorways were narrow, and everything was on different levels, up and down steps,” Janet recalls. “We wanted to move to a home where we could stay if we were to become infirm ourselves, so we started looking locally for something more suitable” — but without much success. An estate agent they consulted about selling their house pointed out that potential buyers looking at the large garden, in such a convenient location, would immediately apply for permission to build one or even two new dwellings there.

After the initial shock that Janet’s much loved garden might be destroyed by a stranger’s digger, a solution presented itself: they could develop the garden themselves. That way they could design a truly all-ages friendly home, continue to enjoy every single advantage of the location, and even retain a little of Janet’s planting.

But as well as having a ‘lifetime home’, Janet and Bernard had another overriding priority: “We were committed to the new home being green. It’s really important for the next generations to leave that legacy.”

So, the couple set about finding out exactly what ‘green’ meant.

“We found that some of the things that are described as ‘eco-friendly’ weren’t really so eco-friendly after all.”

The couple spent “an awful lot of time on the internet”, but a breakthrough came when an acquaintance in the construction industry advised them that the key to getting a genuinely eco-friendly building was to get a really good builder.

“He warned us that most builders would not build to the standard we wanted,” Janet says.

On this basis they identified Bristol-based construction firm Greenheart Sustainable Construction as a firm who really understood sustainability.

“Greenheart were very clear that building a high performance, genuinely low footprint building would cost more. They wanted to make sure we understood — I think Malcolm was interviewing his clients!”

They brought their preliminary design to Greenheart and asked them to quote to build it. Greenheart’s Malcolm McMahon got a good sense of Janet and Bernard’s commitment to genuine environmental performance – and after looking at the initial design proposals told them that he did not believe the design would achieve what they wanted.

However, Malcolm knew a couple of people who could help. Greenheart share an office with passive house consultant Piers Sadler and architect Jeremy Dain, so Malcolm suggested the couple seek their design advice.

“Our target was to be eco-friendly without going mad,” Janet says. “Piers explained to us that our initial design was too complicated and had a lot of glass on the north side. It was not thermally efficient and would be complicated to build.”

Embracing passive house

This article was originally published in issue 33 of Passive House Plus magazine. Want immediate access to all back issues and exclusive extra content? Click here to subscribe for as little as €10, or click here to receive the next issue free of charge

The couple were not especially set on any particular standard, but recognised that the timber framed passive house approach being recommended to them would deliver a home that would be comfortable, extremely low impact, and have low running costs.

As Greenheart’s Richard Hateld recalls: “They were very open-minded. While they weren’t specifically interested in passive house to begin with, they researched a lot and learned a lot, and embraced it really.”

Architect Jeremy Dain agrees: “Having a client keen to build an exemplar building was a big bonus. They were very keen to be cutting edge and remarkably open to learning. Terrifying clients really — always ahead of you! It made it a really enjoyable process.”

Apart from some ground issues (the soil is impermeable, and shrinkable, clay) Jeremy Dain says the site was “a gift”.

At Jeremy’s suggestion, an early decision was made to move the house to the back, north, edge of the plot, fitting the new house between the client’s old house to the east, and the Victorian terrace/semis to the west, and giving an ideal orientation for both passive solar gain and a good relationship with the garden, which would separate the house from the busy road.

Greenheart use all the techniques of passive house whether or not a client is interested in certification. All their builds are highly airtight and designs “are usually run through PHPP just to check them over,” director Richard Hatfield says.

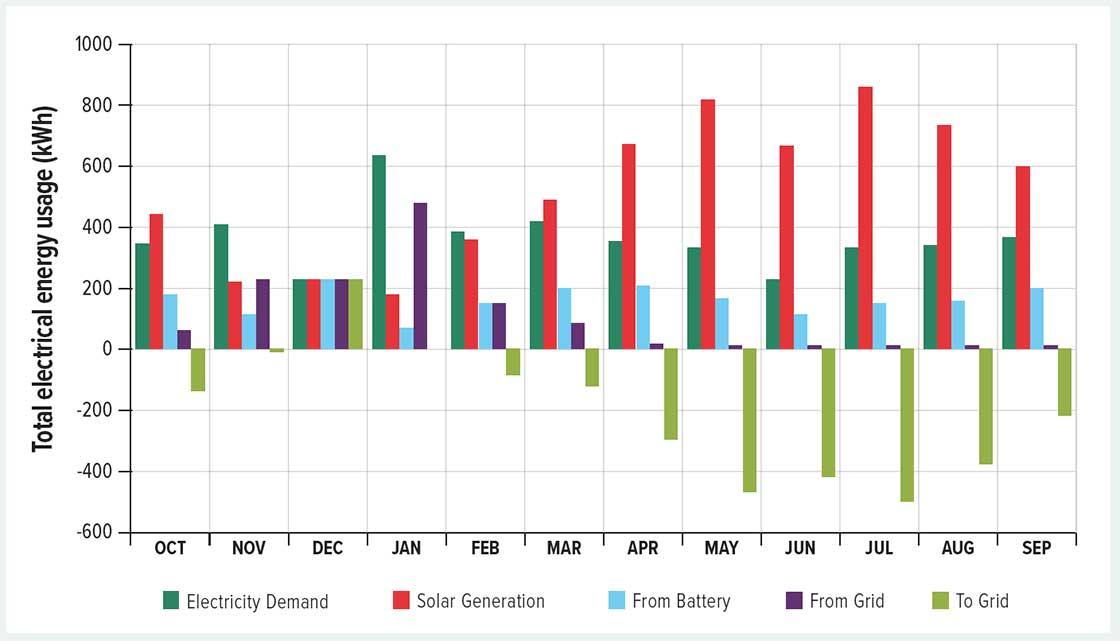

Graph showing total household electricity demand, solar PV generation, and energy exported to and imported from the electricity grid.

They are also committed to low-impact materials and favour a timber framed I-beam construction, filled with cellulose and finished with a wood fibre board insulation and render system. “It’s a fairly easy way to build, and we have our own details, which our team are all familiar with, that we know perform in practice.”

This build used a balloon frame (i.e. with a single wall rising through both storeys) so airtightness and insulation is continuous, and the first floor is hung off the walls. Insulation is at ceiling level, with a trussed roof above.

“Airtightness is achieved by using ProPassiv board for racking – it also provides a vapour control layer, so it does three in one. The board is then taped to everything, we find this easier than taping to membrane which is flapping around.”

Greenheart’s standard floor detail comprises a masonry plinth with an insulated inner leaf of lightweight block, with lightweight blocks supporting internal walls.

“We use 300 mm EPS under the slab – it is cheaper, and the fact that it is thicker than a higher-performance foam to the same U-value is an advantage, as the heat loss path through the concrete block is longer, reducing cold bridging.”

Simple form

He warned us that most builders would not build to the standard we wanted.

The team kept the building form simple, though the clients opted for a small stepped out porch and study. Bernard and Janet preferred the appearance but this form was also driven by space constraints – in particular accommodating the lift that would assure them they could remain in their home for as long as possible.

“It did mean we had to build a lean-to roof, which was harder to detail for airtightness, as the structure passed though the main airtightness layer,” Jeremy Dain explains.

However for the most part, Greenheart already had a well-worked out set of details for their construction system, which meet passive house requirements for airtightness and lack of thermal bridging.

“Greenheart are familiar with exactly what they are doing. It is really great to be able to use their expertise, so the details are ones that they know work on site,” says Jeremy Dain.

“The fact we all work together in the same office resembles the best aspects of design and build – everyone contributes to the process. Working closely with everyone makes the process much easier.”

The finished house is a modest size, but the feel is spacious, and it would work well for a young family too. They might have built slightly smaller, but in order to ensure a home where they could stay even if they lost mobility, circulation spaces and bathrooms were sized to accommodate wheelchair use.

There is also scope to convert a downstairs office to an en-suite bedroom, and space upstairs to accommodate long-term guests (they have had students living with them, for example) or overnight carers.

In keeping with their wish to do right by the future, Bernard and Janet were keen to make the most of the south-facing roof and install a solar PV array – in fact, rather than use conventional roofing material on the south slope of the roof, an integrated PV roofng system covers the entire area, generating more than the house consumes (see ‘In detail’ for more).

Heating and hot water are provided by a 4 kW Mitsubishi EcoDan CO2 refrigerant air source heat pump (a relatively new development, as most heat pumps on the market still contain hydrouorocarbon (HFC) refrigerants).

The improved performance of heat pumps, alongside the dramatic fall in the carbon content of grid electricity (as more renewables come on-stream, and coal power plants are retired) means that although fundamentally an electrically powered system, heat pumps now represent a fairly low carbon option – something that has changed even in the five years this project was in gestation.

“I was always a huger resister of electric heating,” Jeremy Dain admits. “Electricity is a high-grade energy and heat is the lowest grade form. But when you are using so little of it, as you do with a heat pump in a passive house, the picture changes.

Piers Sadler explains the choice of a CO2 (offically known as R744) refrigerant heat pump. “Because of the slightly different physics of CO2 compared to HFCs, these pumps work more efficiently than conventional pumps at the higher temperatures needed for hot water. In contrast to a conventional house, in a passive house, as in an apartment, hot water is a relatively high proportion of the load.

“But what I really like about it is that it uses CO2 and not a high GWP [global warming potential] refrigerant. HFC leakage over the unit lifetime can have a significant overall climate impact.”

When Passive House Plus visited on an icy January morning, the house was wonderfully warm and inviting, the heated floor blissful beneath frozen toes. Underfloor heating is unquestionably a luxury — and in a less efficient envelope, it is also one of the easier ways to provide an unobtrusive, giant-sized heat emitter that will work well with a heat pump.

In a passive house, as Jeremy Dain points out, underfloor heating probably isn’t necessary. “Underfloor heating is lovely to have, but a passive house is so well insulated you can run the heating at the low temperatures that work well with a heat pump, even just with radiators.”

And as Piers Sadler added, the radiators would not need to be very big – and would definitely be cheaper.

-

Erection of the Ibeam timber frame structure

Erection of the Ibeam timber frame structure

Erection of the Ibeam timber frame structure

Erection of the Ibeam timber frame structure

-

PROPASSIV OSB provides airtightness and vapour control

PROPASSIV OSB provides airtightness and vapour control

PROPASSIV OSB provides airtightness and vapour control

PROPASSIV OSB provides airtightness and vapour control

-

Pavatex Diutherm wood fibre board fitted externally to the timber frame

Pavatex Diutherm wood fibre board fitted externally to the timber frame

Pavatex Diutherm wood fibre board fitted externally to the timber frame

Pavatex Diutherm wood fibre board fitted externally to the timber frame

-

300 mm Warmcel insulation installed in the main loft

300 mm Warmcel insulation installed in the main loft

300 mm Warmcel insulation installed in the main loft

300 mm Warmcel insulation installed in the main loft

-

Thermal bridge reduction included mineral wool

Thermal bridge reduction included mineral wool

Thermal bridge reduction included mineral wool

Thermal bridge reduction included mineral wool

-

Thermal bridge reduction included PIR in front of steel Ibea

Thermal bridge reduction included PIR in front of steel Ibea

Thermal bridge reduction included PIR in front of steel Ibea

Thermal bridge reduction included PIR in front of steel Ibea

-

Thermal bridge reduction included AAC lightweight concrete blocks at floor level

Thermal bridge reduction included AAC lightweight concrete blocks at floor level

Thermal bridge reduction included AAC lightweight concrete blocks at floor level

Thermal bridge reduction included AAC lightweight concrete blocks at floor level

-

Thermal bridge reduction included PIR around the outside of the rooflight shaft

Thermal bridge reduction included PIR around the outside of the rooflight shaft

Thermal bridge reduction included PIR around the outside of the rooflight shaft

Thermal bridge reduction included PIR around the outside of the rooflight shaft

-

60 mm XPS was installed at plinth level to protect wood fibre insulation boards from rain splash due to varying ground levels

60 mm XPS was installed at plinth level to protect wood fibre insulation boards from rain splash due to varying ground levels

60 mm XPS was installed at plinth level to protect wood fibre insulation boards from rain splash due to varying ground levels

60 mm XPS was installed at plinth level to protect wood fibre insulation boards from rain splash due to varying ground levels

Passive house powerhouse

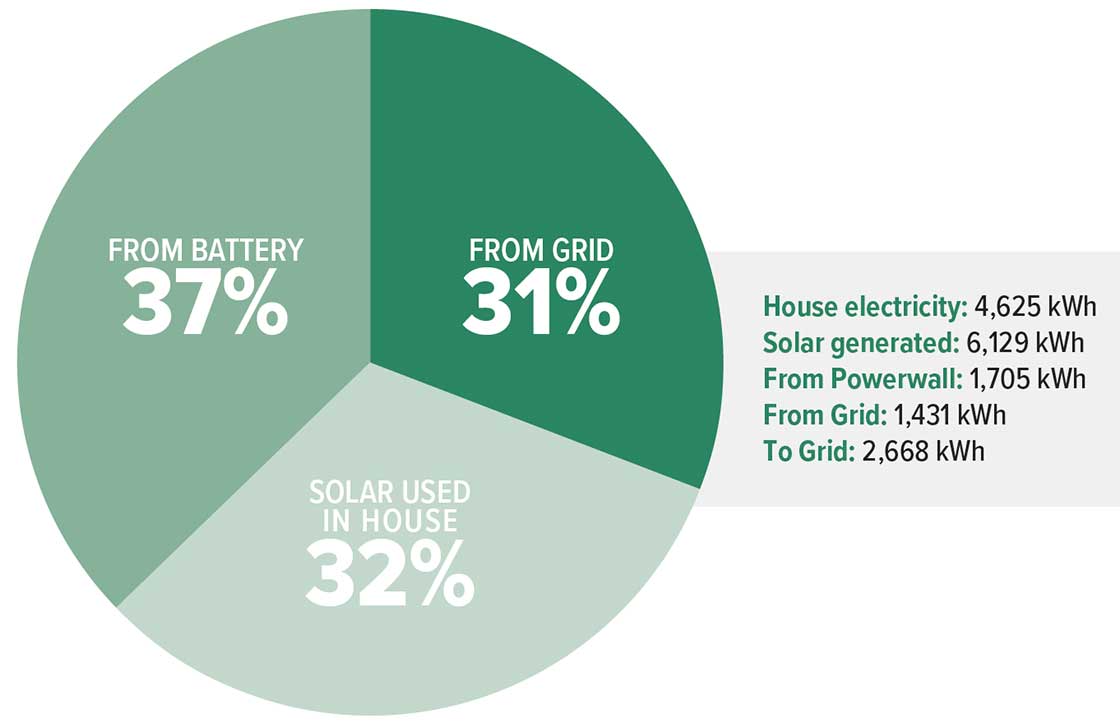

Bernard and Janet were keen to reduce the burden on the grid further, by using a battery to save some of their solar energy for use after dark, when grid load tends to rise. Although they are fairly expensive to buy, the calculations Piers Sadler carried out suggested that the battery (a Tesla Powerwall) would pay for itself in terms of fuel bill savings comfortably before its 20-year guarantee expired.

When the shell of the house was complete, the passive house-friendly design and Greenheart’s meticulous construction meant that the airtightness level was an impressive 0.3 air changes per hour. It was clear that certication was going to be possible.

Bernard and Janet consulted a few local estate agents about whether there was a value in doing so. “Most of them either didn’t know what we were talking about or doubted it would make any dierence, but one did say that if they could get a certificate then that would be worthwhile.”

The passive house ‘plus’ certification however came about more or less by accident.

The house’s plant room, and undercuts of circa 30 mm beneath internal doors to aid air circulation.

“We didn’t do anything in particular to achieve that standard, it really wasn’t on our radar,” Piers Sadler explains.

“We were only thinking about achieving the performance for a classic passive house, and I was very much focused on the heat demand side.” (This tends to be the most demanding aspect of passive house with a modest-sized detached dwelling like this one).

“But because the clients were keen on having the PV roof, and because heat pumps have such low primary energy demand, when the certifiers looked at our figures they told us that we had met the passive house plus standard anyway.”

Bernard and Janet moved in a little over a year ago, and so far the house has certainly met their expectations. Although they are very keen to log all the data for the heat pump, PV roof and battery, the fact that manufacturers regularly update their software and change the way the data is saved and displayed is not always helpful, they say.

Nonetheless, from the data they do have, the early indications are that in a mild winter (2018/2019) at least, the house uses even less heating than predicted in PHPP, andtotal energy use is also comfortably below predictions.

Now it is clear that the tiny upstairs radiators are never needed, the system is undergoing some fine-tuning, after which it should be possible to properly assess the heat pump’s co-efficient of performance, too.

Based on the monitored performance so far, the building is comfortably meeting the operational energy target in the 2030 RIBA Climate Challenge, namely a primary energy total (including regulated and unregulated energy) of less than 35 kWh/m2/yr, a space heating demand of less than 20 kWh/m2/yr, the absence of a fossil fuel boiler, and the ofsetting of remaining emissions via contributing to UK renewable energy projects (in this case, there was no need to offset, given the building’s net export of energy to the grid).

The home’s simple form and clean white appearance sits comfortably among the mixture of styles and ages in the road. As Janet says: “So many of the passive house homes we saw doing our research were either social housing – which is great, but almost always quite small, and terraces or apartments, so not what we wanted – or they looked like they belonged on millionaire’s row.”

“We are passionate about demonstrating how a normal, family home can really do the right thing for the environment, do the right thing for future generations. We really believe all homes should be like this.”

Keeping it modest

One of the clients’ aims was to show others – including their local authority – that high-performing, eco-friendly housing need not look outrageous, nor cost an outrageous amount of time or money to build.

“Compared to what we see in many self-build designs, this build did not have very large spans: this is a huge advantage especially when you are building for high energy performance,” Richard Hatfield of Greenheart Construction explains.

“When clients want big open plan living spaces or long runs of continuous floor to ceiling glazing, you end up having to put in big steels to support the span and get enough rigidity. And then you get thermal bridging issues.

“We can insulate a steel [beam] enough to prevent any moisture risk, but you can’t match the insulation value of the rest of the wall, which means you need to increase the performance elsewhere, for example by making all the walls thicker.

You face a similar situation if you have a lot of north-facing glazing.

“As the span gets larger, the steel has to get thicker, and with the biggest spans you can end up with a 300 mm deep beam – which can’t be accommodated within the thickness of a normal wall, meaning you then need to go to a non-standard structure to accommodate it – such as cantilevering floors out over the top of the steel.

“Complicated and one-off details are always harder to achieve on site, because they are less familiar. Our team really know what they are doing with our standard details, but something non-standard requires more design time and more supervision, and therefore costs the client more.”

While natural materials such as cellulose insulation and wood fibre board mean “significant cost uplift” over petrochemical foams, as Jeremy Dain explains, he adds that the simple form and modest finishes such as render, tile and timber cladding kept costs under control, as well as giving the house a fairly “normal” appearance.

Where does the house's electricity come from?

This chart shows shows a neat split between solar generation used directly, energy drawn from solar power stored in the battery, and grid imports, from October 2018 to September 2019.

From April to September last year, the house was almost completely (98%) self-sufficient in energy. Inevitably imports rise in winter, but even in the two coldest, darkest months, 20-25% of the house’s total electricity was home-generated: in fact, in January 2020 the figure was a respectable 31%.

From April to September last year, the house was almost completely (98%) self-sufficient in energy. Inevitably imports rise in winter, but even in the two coldest, darkest months, 20-25% of the house’s total electricity was home-generated: in fact, in January 2020 the figure was a respectable 31%.

There do appear to be storage losses, with the energy drawn from the battery apparently being 14% less than that put in. However, as with the heating performance of the house, these are preliminary figures only.

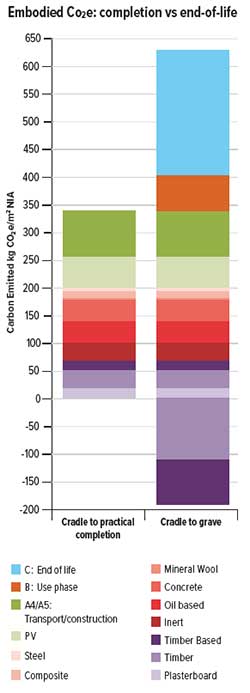

Embodied carbon

Builders Greenheart Construction commissioned Tim Martel, the creator of PHribbon, a PHPP-based tool which includes a life cycle assessment tool, to run the numbers.

The house has a total embodied carbon score up until practical completion stage of 338 kg CO2e/m2, disregarding sequestered CO2 in the timber and timber-based products. The cradle-to-grave figure works out at a net score of 437 kg CO2e/ m2, a figure which beats the 2025 target under the RIBA 2030 Climate Challenge. This figure includes the embodied energy for a large PV array, while ignoring the considerable operational carbon reduction this will generate. The figure would drop substantially if the timber and timber-based products avoided incineration at end of life.

What is a passive house 'plus'?

A building certified to the passive house ‘plus’ standard not only drastically reduces energy use like a passive house ‘classic’, but it is also designed to produce as much energy on site as occupants consume. The energy generated must come from renewable sources and provide enough energy to operate the building throughout the whole year.

It requires a minimum of 60 kWh/ yr of renewable energy generation for every square metre of the building’s footprint (as opposed to floor area), along with a maximum renewable primary energy (PER) demand of 45 kWh/m2/yr of floor area: this is the amount of electricity drawn from a theoretical future electricity grid which is powered 100% by renewables. The even more advanced passive house premium standard requires generation of 120 kWh/m2/yr and a maximum PER of 30 kWh/m2/yr.

The targets for space heating demand (15 kWh/m2/yr) and heat load (10 W/m2) remain the same with all versions of the standard.

Selected project details

Architect: S2 Architects

Contractor: Greenheart Sustainable Construction

Civil & structural engineering: Element Structures

Energy consultant: Piers Sadler Consulting

Passive house certifier: WARM

Building services contractor: Solarsense

Airtightness tester: BAT

Wall & roof insulation: Warmcel, via Greenheart

Additional wall insulation: Natural Building Technologies

Airtightness & vapour control board: MEDITE SMARTPLY

Airtightness membrane: Ecological Building Systems

Windows & doors: Rationel, via Greenmoose

Roof windows: Fakro

Heat pump: Mitsubishi Electric Ecodan, via Solarsense

MVHR: Green Building Store (supply); Greenheart (install); Fourwalls (commissioning) Solar PV: Solarsense

In detail

Building type: 153 m2 detached, two storey, timber frame house

Location: Nailsea, Bristol, UK

Completion date: July 2019

Passive house certification: Certified passive house plus

Space heating demand: 16 kWh/m2/yr

Heat load: 10 W/m2

Primary energy renewable (PER) demand: 44 kWh/m2/yr

Heat loss form factor: 3.17

Overheating fraction (PHPP): 4% (of time above 25C)

Number of occupants: 2

Environmental assessment method: N/A

Airtightness: 0.35 ACH @ 50 Pa

Energy Performance Certificate: A (105)

Measured energy consumption (Oct 2018 to Sept 2019): 4,625 kWh/yr measured TOTAL electrical consumption for 12 months, including space heating & hot water, according to Tesla Powerwall app. Divided by 153 m2 total fl oor area gives a figure of 30 kWh/m2/yr electrical consumption. Of this 1,312 kWh is used by the heat pump to provide space heating & hot water.

THERMAL BRIDGING

External wall-floor: Lightweight concrete block at plinth level below inner chord of ibeam stud.

Internal wall-floor: Lightweight concrete block; steel frame around double sliding door internal with Rockwool in timber frame on the outside; for SAP calculation ACDs used for thermal bridging.

Energy bills: The house is all electric. Between 19/09/2018 & 02/09/2019 the clients paid a total £253.32 for grid electricity but received a £415.49 feed-in-tariff for exporting electricity to the grid, making a £162 profit on annual energy bills.

Ground floor: 225 mm concrete followed above by 300 mm PIR, 75 mm screed, 25 mm wood fl ooring. Uvalue: 0.074 W/m2K

External walls: Baumit SilikonTop render with MC55 base coat (or cavity and larch rainscreen) externally, followed inside by 60 mm Pavatex Di utherm, 300 mm Ibeams insulated with Warmcel, 12 mm ProPassiv OSB, 25 mm services cavity, 15 mm plasterboard and skim. Uvalue: 0.11 W/m2K

Trussed roof: GBSol roof integrated solar PV system to south roof; concrete tiles on breathable roofing membrane to north roof. 300 mm Warmcel on the flat, bridged by timbers at 10%, followed beneath by 12 mm ProPassiv OSB, 25 mm services cavity, 15 mm plasterboard and skim. Uvalue: 0.132 W/m2K

Windows and external doors: Rationel Aura Plus solid timber with aluminium cladding, triple glazed, argon filled low E. Average Uvalue circa 0.90 W/m2K. GBS Ultra sliding window, solid timber, triple glazed, argonfilled low E. Average installed Uvalue: 1 W/m2K

Roof window: Fakro FTT U8 Thermo. Installed Uvalue 1.01W/m2K

Heating system and hot water: Mitsubishi Ecodan QUHZW40VA /EHPT20QVM2EA air source heat pump and thermal store, supplying underfloor heating and radiators direct from the heat pump and domestic hot water from the thermal store. Heat pump uses CO2 as its refrigerant eliminating the risk of leakage of high global warming potential refrigerants through the life of the unit. Seasonal COP approx. 2.9. Thermal store standing heat loss 1.63 kWh/24hrs

Ventilation: Passive house certified Paul Novus 300 MVHR, 93% efficient.

Electricity: 7.23 kW roof integrated GBSol PV. Tesla Powerwall 13 kWh battery. Solar output in first year 6,129 kWh. Battery output in first year 1,705 kWh. Battery losses 17%.

Green materials: Timber frame construction, Warmcel and Pavatex Diffutherm insulations.

Image gallery

-

A102 window installation details

A102 window installation details

A102 window installation details

A102 window installation details

-

A104 section details

A104 section details

A104 section details

A104 section details

-

A105 section details

A105 section details

A105 section details

A105 section details

-

A107 service entries

A107 service entries

A107 service entries

A107 service entries

-

A108 service entrie

A108 service entrie

A108 service entrie

A108 service entrie

-

A113 threshold detail

A113 threshold detail

A113 threshold detail

A113 threshold detail

-

A115 plan detail

A115 plan detail

A115 plan detail

A115 plan detail

-

A116 section details

A116 section details

A116 section details

A116 section details

-

A117 window installation details

A117 window installation details

A117 window installation details

A117 window installation details

-

A118 section details

A118 section details

A118 section details

A118 section details

-

A120 section details

A120 section details

A120 section details

A120 section details

-

A121 section details

A121 section details

A121 section details

A121 section details

-

CurrentRISE-170511

CurrentRISE-170511

CurrentRISE-170511

CurrentRISE-170511

-

L43 FF plan GA

L43 FF plan GA

L43 FF plan GA

L43 FF plan GA

-

L45-B roof plan

L45-B roof plan

L45-B roof plan

L45-B roof plan

-

L46-B elevations

L46-B elevations

L46-B elevations

L46-B elevations

-

L47-C elevations

L47-C elevations

L47-C elevations

L47-C elevations

-

L49-A elevations

L49-A elevations

L49-A elevations

L49-A elevations

-

L50-A elevations

L50-A elevations

L50-A elevations

L50-A elevations

-

L51 key section-1

L51 key section-1

L51 key section-1

L51 key section-1

-

L51 key section

L51 key section

L51 key section

L51 key section

-

superceded A104-A section details revised parti

superceded A104-A section details revised parti

superceded A104-A section details revised parti

superceded A104-A section details revised parti