- Insight

- Posted

Carbon first, fabric second

What is the best way to decarbonise the UK’s homes? This question has sparked heated debate over the past year.

On one side are those who believe we should deep retrofit dwellings through insulation and airtightness measures, slashing their energy demand and making them more resilient, more comfortable, and less vulnerable to fuel poverty. In other words, put building fabric first.

On the other side, those who say retrofit is simply too slow and complex, that we should worry less about energy efficiency and prioritise getting low carbon heat — in particular, heat pumps — into homes as quickly as possible. So, who is right? Arguably, both are.

The exterior of Tystean Lea’s house, which he did not insulate; Lea installed some large surface area radiators; and retrofitted a Mitsubishi EcoDan heat pump.The home is listed on heatpumpmonitor.org, with 30 day mean COPs of 4 or over at the time of writing in December.

The exterior of Tystean Lea’s house, which he did not insulate; Lea installed some large surface area radiators; and retrofitted a Mitsubishi EcoDan heat pump.The home is listed on heatpumpmonitor.org, with 30 day mean COPs of 4 or over at the time of writing in December.

The evidence shows that, done well, deep retrofit shrinks energy demand and improves the lives of building occupants. But so-called ‘heatpumpification’ is a faster and cheaper way to reduce the carbon footprint of buildings.

Now, the AECB is aiming to forge a middle way, creating a pathway for homes to get a heat pump and shallow retrofit now, but prepare for a deep retrofit in future. The group has relaunched its CarbonLite (Carbon Literate Design and Construction) standards, providing three pathways to better buildings.

CarbonLite Retrofit step-by-step

In the new step-by-step approach to Carbon- Lite Retrofit (CLR), the home is fitted with a heat pump and good ventilation initially and receives just enough insulation and draughtproofing to ensure the heat pump operates efficiently and affordably (step one). A sensible plan is developed for the building to reach the full CarbonLite Retrofit standard in future (in a single second step, or multiple steps).

CarbonLite Retrofit completed

A whole-house deep retrofit standard, designed to dramatically cut energy use, with a maximum space heating and cooling demand of 50 kWh/m2yr (by comparison, the Passive House Institute’s Enerphit standard requires 25 kWh/m2yr).

Glyn Hudson’s house features a Samsung Gen 6 air source heat pump. This home is listed on heatpumpmonitor.org, with 30 day mean COPs of 4 or over at the time of writing in December.

CarbonLite New Build

A rigorous new build standard, with a space heating and cooling target of 40 kWh/m2yr (by comparison, the passive house classic standard requires 15 kWh/m2yr).

The CarbonLite standards are all based on the rigorous passive house methodology and require energy modelling using the Passive House Planning Package (PHPP). Carbon- Lite standards can also be applied to non-domestic buildings.

Fabric first or fabric second?

The AECB has a long history with building standards. The group first launched its CarbonLite Bronze, Silver and Gold standards in the mid 2000s, to reflect UK-specific building types and the skill profile of the UK’s building industry. It then launched the Passivhaus Trust in 2010 to mainstream radical energy efficiency, leveraging the international momentum that had built up around the German standard. The Carbon- Lite Retrofit standard was launched in 2021.

But the latest incarnation of CarbonLite Retrofit marks a shift from the AECB’s fabricfirst roots. The CLR step-by-step approach prioritises quick and effective climate-action, putting the low-carbon heating system first (including the heat emitters, e.g., radiators or underfloor heating), enhanced by modest fabric and ventilation measures. Chief executive Andrew Simmonds is pragmatic about why the AECB has changed its approach.

“Our culture and institutions are not changing fast enough to safeguard society from peak oil and the shockingly fast effects of ever worsening climate breakdown,” he says. “There is a profound failure of national political leadership, a lack of science-based policymaking, and a desperate shortage of the necessary skills — all necessary to deliver healthier new and retrofitted low carbon buildings at a meaningful scale and pace. Even without cultural and institutional inertia, and the dangerous and short-sighted delay from heavily vested interests such as the fossil fuel industry, such change takes decades, and we have kicked the can down the road for too long. Hence, we are forced to rethink previously hard-won positions.”

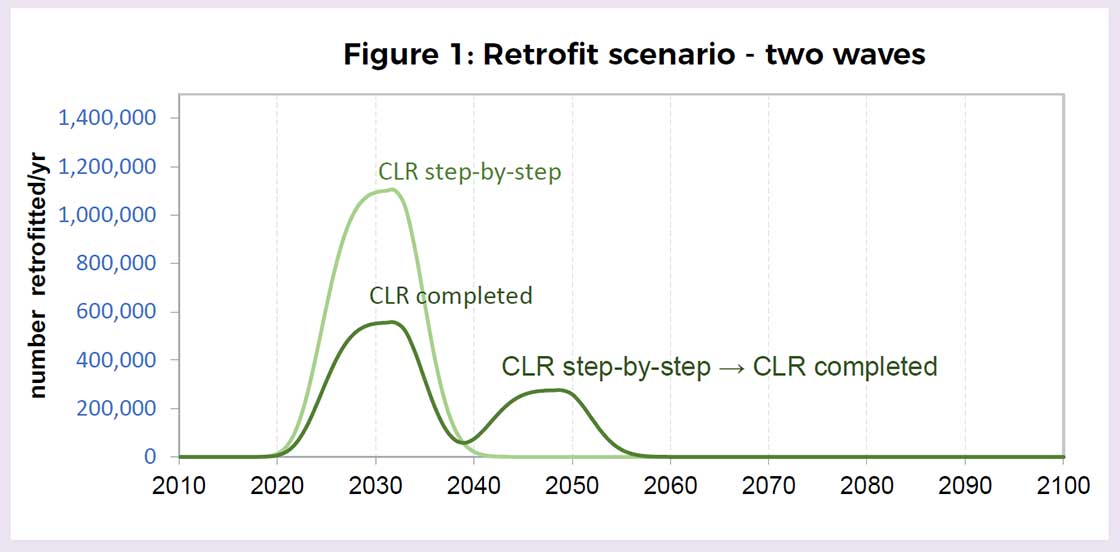

Figure 1. An AECB stock model scenario showing two retrofit waves to the English housing stock. In the first wave, 50 per cent of stock takes the step-by-step approach to CarbonLite Retrofit, while 25 per cent of stock goes straight to full CarbonLite Retrofit. In the second wave, the projects which had already started the step-by-step approach are upgraded to full CarbonLite Retrofit by the middle of the century.

CarbonLite Retrofit step-by-step: Heat pumps now for rapid decarbonisation

The UK government is aiming to install 600,000 heat pumps a year from 2028, but just 54,000 were installed in 2022. The heat pump rollout has been plagued by stories of high running costs and poorly designed systems, but some of this is simply malicious misinformation. The primary aim of the CarbonLite Retrofit step-by-step approach is to ensure heat pumps run efficiently, and do not increase energy bills, allowing fast and deep decarbonisation of a building’s space and water heating.

“Our housing stock modelling looked at space heating emissions from UK housing, and also incorporated upfront carbon emissions from building materials and construction. It indicated that a smaller wave of the deeper CarbonLite retrofits along with a much larger wave of CarbonLite step-bystep retrofits over the next few years would deliver a huge reduction in carbon emissions. This even factored in the up-front carbon emissions from manufacturing the heat pumps,” says Simmonds.

“Also, critically important is to reduce the performance gap, which leads to homeowners’ energy bills and greenhouse gas emissions being higher than expected. Our step-by-step retrofit standard is designed to support installers, and ensure excellent heat pump design and installation quality in these low capital cost retrofits.”

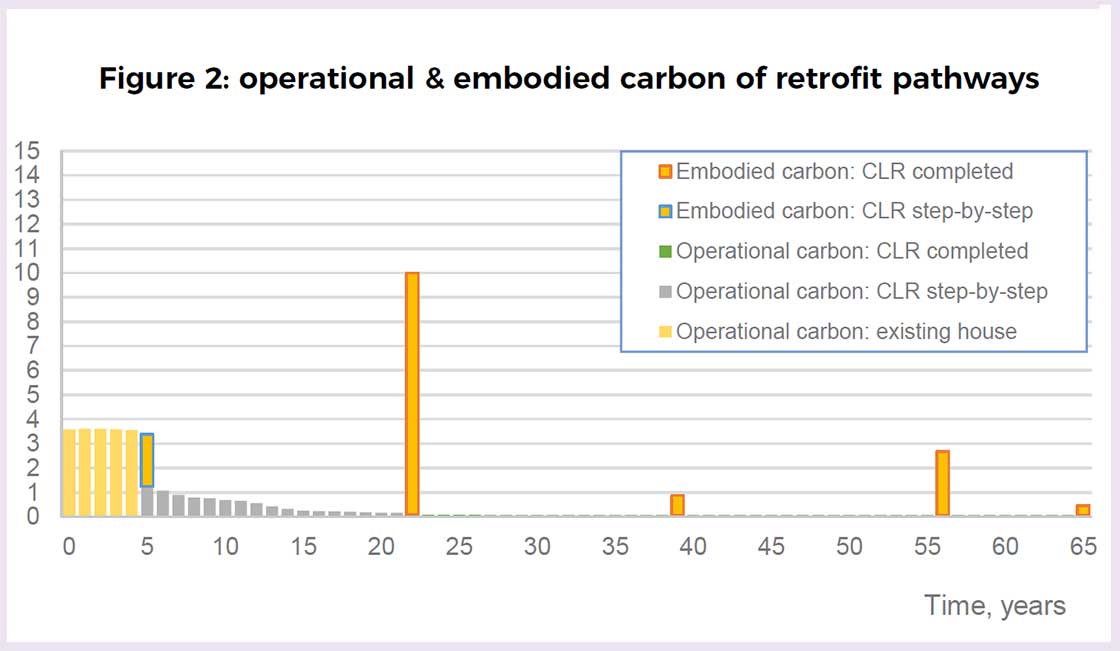

When the heat pump is due for replacement after 17 years (in year 22) the Carbon- Lite Retrofit is completed including deeper fabric measures and a smaller heat pump - and lifting the temperature to 20 C. For the full retrofit the figures are for external wall insulation (but internal wall insulation gives similar figures. Standard occupancy of 2.4 people per house was assumed.

The AECB stock model looks at electricity demand in the various scenarios in addition to carbon. It also considers peak heating demand on the national grid in winter. The model reports that a subsequent wave of CarbonLite Retrofits in about 20 years’ time would help to minimise peak demand on the electricity grid. This second wave would include more full retrofits as well as step-by-step retrofits that are further improved, following their whole house plans.

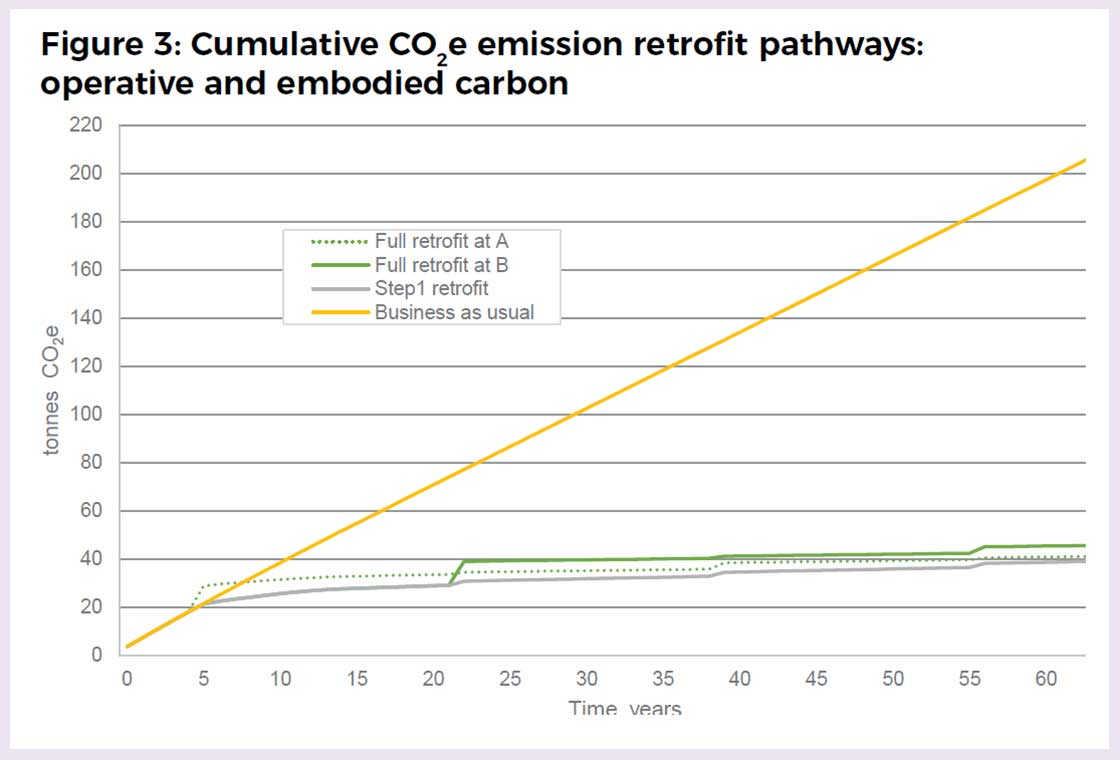

Both AECB large scale stock modelling and individual house type modelling show ‘bumps’ in greenhouse gas emissions at intervals due to the upfront carbon of retrofit, with larger bumps for deeper retrofits. But while important to factor in, these bumps are dwarfed over time compared to a business-as-usual scenario (‘do nothing’).

Figure 2. This graph gives annual emissions from space heating, embodied carbon and thermal comfort data across different phases of an existing house. For the first five years the house remains heated by gas, and is heated to 17.8 C. After five years a CLR step-bystep retrofit is done, including switching from gas to an air source heat pump, and a slight increase in thermal comfort to 18.1 C. The annual emissions decline for the next 17 years, as the heat pump benefits from decarbonising grid electricity. When the heat pump is due for replacement after 17 years (in year 22) a CarbonLite Retrofit is completed including deeper fabric measures and a smaller heat pump - and lifting the temperature to 20 C. For the full retrofit the figures are for external wall insulation (but internal wall insulation gives similar figures. Standard occupancy of 2.4 people per house was assumed.

Low bills, good health: The CarbonLite journey

At the outset, a step-by-step retrofit aims to improve the building fabric just enough that the heat pump can operate at a flow temperature below 50 C – and ideally well below.

This keeps energy bills under control, but without the need for a disruptive, expensive deep retrofit now. To provide healthy indoor air, the standard also requires either mechanical ventilation with heat recovery, or simpler and cheaper mechanical extract ventilation.

For step-by-step certification, AECB certifiers must also ensure a longer term deep retrofit strategy is in place to further reduce energy use and operational emissions, and deliver other benefits such as improved comfort and health. This provides a clear long-term pathway to a net-zero carbon home or workplace, without creating a false choice between either ‘heatpumpification’ or ‘deep retrofit’.

“With this approach, you’re creating a ‘route map’ for each building, and a journey for the owners, and saying ‘let’s see how far along the journey we can bring your building’,” says Passive House Plus editor Jeff Colley, who is also chair of the Heat Pump Association of Ireland, and a board member of the Passive House Association of Ireland. “I think that’s really compelling — and with the same building physics of passive house behind it, the same rigour.”

Sally Godber of leading passive house certifier WARM sees CarbonLite Retrofit step-by-step as a great starting point on the retrofit journey. “I’m really excited about this approach. In the void of funding and policy for retrofitting homes it’s a great solution for homeowners that want to do something to make a difference but can’t afford a full Enerphit. It’s well thought through and ensures that future measures aren’t compromised.”

CarbonLite Retrofit: a risk reductionbased approach to retrofit

The full CarbonLite Retrofit standard requires a maximum space heating and cooling demand of 50 kWh/m2yr. That usually necessitates a deep retrofit. A CarbonLite Retrofit may replace a gas boiler with a heat pump, but it also allows existing heating systems to be retained if necessary (for example if a new boiler was only recently installed).

“The standard offers a bit more flexibility than Enerphit,” says AECB certifier Paul Mallion. “It’s less prescriptive, therefore it can cope with smaller dwellings, older or more complicated ones that have a poor form factor.”

Passive house and AECB certifier Sarah Price, who helped to develop the Carbon- Lite Retrofit standard, echoes this. “I think it’s the best retrofit standard we have in the UK,” she says. “It’s pragmatic and is going to be applicable to many more buildings than Enerphit. I’ve done my fair share of Enerphit projects, and whilst they do have their place, and are fantastic projects, they are challenging and costly, especially in residential where residents have to, or want to, stay in their homes during the retrofit.”

Price particularly likes the way Carbon- Lite ensures the project team considers key risk factors like building condition, moisture risks, flooding, fire, and radon, which are not required for passive house certification.

Certifiers can allow some pre-approved exemptions from the 50 kWh/m2/yr rule — up to a max of 100 kWh/m2/yr — for specific reasons, such as building conservation, fire or moisture risk. By checking with a fellow certifier and logging their discussion (the ‘buddy system’), certifiers may also approve exemptions for other “compelling reasons”.

One such reason might be “if some deeper retrofit measures would emit significant amounts of upfront carbon”, Simmonds says.

In such an instance, the AECB encourages its certifiers to justify the exemption with a whole life carbon calculation. As the scheme builds up a body of evidence from the certification of more projects, the process should become simpler and less onerous, with more approaches becoming standardised or pre-approved.

Figure 3. Cumulative greenhouse gas emissions from heating a typical UK semi-detached home. Business as Usual is a gas heated, unimproved home – which shows an unrelenting accumulation of greenhouse gas emissions into the atmosphere over 60 years, compared to dramatically reduced emissions from both the Step 1 and full CarbonLite retrofitted property. Retrofitted dwellings also deliver more comfortable, healthy and climate-resilient homes – key ‘non-energy’ benefits.Any emissions arising from decommissioning, stripping out, disassembly, deconstruction and demolition operations as well as from transport, processing and disposal of materials must be accounted for at the end of the reference study period, even if they do not necessarily happen at this time. For the purpose of this example, the standard 60 year reference period has been set to start at point A (for both full and step 1 retrofits). For the full retrofit starting at point B, we have brought forward end of life emissions so that they appear on the graph and figures are for external wall insulation, as for the previous graph. (Internal wall insulation using woodfibre gives an almost identical result after end of life emissions).

CarbonLite New Build: Closing the performance gap

CarbonLite New Build, previously called the AECB Building Standard, is aimed at new homes. It requires a space heating and cooling demand of 40 kWh/m2/yr. This standard is increasingly popular with housing associations, developers and local authorities seeking to provide healthy low energy dwellings. Recent projects include a large social housing estate in Castletown on the Isle of Man, numerous schemes across the south of England for Hastoe Housing Association, and an 88-home development by Stonewood Homes in Gloucestershire.

In Wales, social housing projects must achieve an energy performance certificate (EPC) of A, or be certified to an alternative low energy standard, to qualify for state funding. CarbonLite New Build is now accepted as such an alternative, following evidence submitted to the Welsh government by Jonathan Davies and Jaime Moya, two AECB certifiers with Spring Design Consultancy in Bridgend.

Davies and Moya previously promoted passive house to housing associations, housebuilders and government, but say that most found the standard too much of a leap. CarbonLite New Build, however, began to open more doors.

"We’ve been on a major outreach programme for the CarbonLite New Build standard to South Wales housing associations and local authorities,” says Moya, who is director of architecture at Spring. “We’re finding that with the AECB standard, the reduction in energy demand, the tangible return for tenants, is there for all to see.”

Moya and Davies’s pitch includes modelling which shows that a typical semi-detached home, built to CarbonLite New Build and with an EPC of B, can achieve half the space heating bills of the same house built to a conventional EPC A specification.

"The CarbonLite New Build standard is attractive, and it’s upskilling the supply chain to a level it can deliver now, so we can work towards higher levels of performance, towards passive house as a new building standard for Wales,” Moya says. “We firmly believe as architects and passive house designers, that it’s up to us to try to make this happen.”

A semi-detached house in Lancaster retrofitted by Coldproof may be the first project to take the new CarbonLite step-by-step approach

-

Existing double glazeThe outdoor unit of the air source heat pumpd windows were retained, existing cavity was pumped

Existing double glazeThe outdoor unit of the air source heat pumpd windows were retained, existing cavity was pumped

Existing double glazeThe outdoor unit of the air source heat pumpd windows were retained, existing cavity was pumped

Existing double glazeThe outdoor unit of the air source heat pumpd windows were retained, existing cavity was pumped

-

Existing double glazed windows were retained, existing cavity was pumped

Existing double glazed windows were retained, existing cavity was pumped

Existing double glazed windows were retained, existing cavity was pumped

Existing double glazed windows were retained, existing cavity was pumped

-

Airtightness membrane retrofitted across stud wall and ductwork void created

Airtightness membrane retrofitted across stud wall and ductwork void created

Airtightness membrane retrofitted across stud wall and ductwork void created

Airtightness membrane retrofitted across stud wall and ductwork void created

-

Underfloor heating installed

Underfloor heating installed

Underfloor heating installed

Underfloor heating installed

-

Internal woodfibre insulation was added.

Internal woodfibre insulation was added.

Internal woodfibre insulation was added.

Internal woodfibre insulation was added.

https://passivehouseplus.ie/magazine/insight/how-to-decarbonise-the-uks-housing-stock#sigProIdf3ae050257

Passive house in new terrain

This article was originally published in issue 46 of Passive House Plus magazine. Want immediate access to all back issues and exclusive extra content? Click here to subscribe for as little as €15, or click here to receive the next issue free of charge

Ultimately, the revised CarbonLite Retrofit standard takes passive house into new terrain, applying it to ‘heatpumpified’ & lightly retrofitted buildings to leverage the decarbonising UK electricity grid — arguably without compromising the rigorous building physics of passive house, and without compromising future deep retrofits.

Sarah Price, however, is keen to see the core focus remain on deep retrofit. “Yes, rapid decarbonisation is the urgent goal, we need to electrify heating, we need to put heat pumps in,” she acknowledges. “But equally for me, we have the worst housing stock in Europe. We have excess summer deaths, excess winter deaths. We could be doing so much better with our houses, and I think we need to be sending that message out saying look, fabric retrofit has many and varied benefits if we get it right.”

The CarbonLite standards are still in their infancy and their applicability and effectiveness in delivering better, low carbon, low energy buildings will continue to evolve as the AECB reflects on a growing amount of real-world feedback. “It’s an experiment of sorts,” says Andrew Simmonds, “but a necessary and urgent one”.

“We are looking to help drive up minimum standards, so that the resources we do have — including the time people have available, the financial capital and materials — are used in a way that rapidly reduces greenhouse gas emissions and improves the health and wellbeing of people living in their homes.”

For more see www.aecb.net