- New build

- Posted

Big time - UK's largest passive scheme comes to Camden

The first phase of the hugely ambitious Agar Grove redevelopment in Camden was finished in April 2018. Not only is it the largest passive house scheme in the UK to date, it also aims to be a model for sustainable urban regeneration and for creating liveable spaces at the heart of our cities.

Click here for project specs and suppliers

£13.50 per month (space heating & hot water, see ‘In detail’ for more)

Building: 38-unit, seven-storey apartment block. Concrete frame & cavity wall construction.

Completed: April 2018

Location: Camden, London

Standard: Passive house certified

Back in early 2012, when Camden Council began talking to the residents of Agar Grove about the proposed redevelopment of their estate, the occupants of one of the blocks – Lulworth Tower – decided to opt out. Unlike the rest of the estate, which was managed by the council, Lulworth was run by a tenant organisation and had an independent management structure.

Throughout that year and into 2013, the council continued the consultation phase for the rest of the residents, running events and exhibitions in the estate’s community space. It was following one of these exhibitions that the Lulworth tenants’ organising committee approached the council and asked if they could opt back in.

“That was really exciting for us,” says Michelle Christensen, senior development manager at Camden Council. “The success of what they saw going on around them generated a high level of trust. We were delighted to begin looking at options for them.”

A rendering of Agar Grove, with block A at the back right

If you could isolate one factor to account for the success of the redevelopment of Agar Grove in its initial stages, it’s has been communication. There has been a free flow of ideas, expertise and feedback between everyone involved: council, residents, designers, contractor, subcontractors and so on.

“Design-and-build contracts don’t normally tend to lend themselves to open dialogue,” says Christensen, “but in Agar Grove, it’s been really essential to making it all work and making it all successful.”

There has been a free flow of ideas, expertise and feedback between everyone involved.

Agar Grove is the largest passive house development in the UK to date, though not all of the proposed 493 homes will be certified passive. The aforementioned Lulworth Tower – owing to its size and the high levels of embodied carbon in its concrete structure – will be stripped down and refurbished to a high (though not quite passive) standard.

This does not take away from the fact that this project is one of the most ambitious that we have covered in Passive House Plus to date.

Urban regeneration

To go back to the beginning, the Agar Grove estate was built in the 1960s. As with much of the local authority housing of that era, the rooms were cold, draughty and expensive to heat. Cold bridges abounded, giving rise to significant damp and mould growth issues.

They were also too small.

“The three-bed units were 69 square metres,” says Christensen, “which is less than London design guide space standards for a two-bed now. Plus, they had odd-shaped, triangular kitchens that you could hardly fit a fridge into.”

If the interior layouts were strange, that went double for the external layouts. There were bedrooms at ground floor level and large empty spaces of uncertain function. Surrounded on two sides by railway and enclosed by a high fence, the whole layout felt defensive and uninviting.

“It was completely detached from the streets around it,” says James Woodward of design architects Hawkins Brown. “There was no logical hierarchy between private and public space. There was a huge ball court tucked into a corner of the site, but no one used it; it wasn’t overlooked and didn’t feel safe.”

The overall context for the project was Camden’s borough-wide community investment programme, which launched in 2010.

This was a systematic analysis of all councilowned assets with a view to building more affordable housing, schools and community facilities, and to invest in the existing housing stock.

At the outset, a variety of options were investigated for Agar Grove – including infill development, and partial as well as complete demolition. At the same time, because this would be Camden’s biggest development, the council was determined that it would be in some way exemplary. Architecture and urban design were key considerations of course, but so too was sustainability.

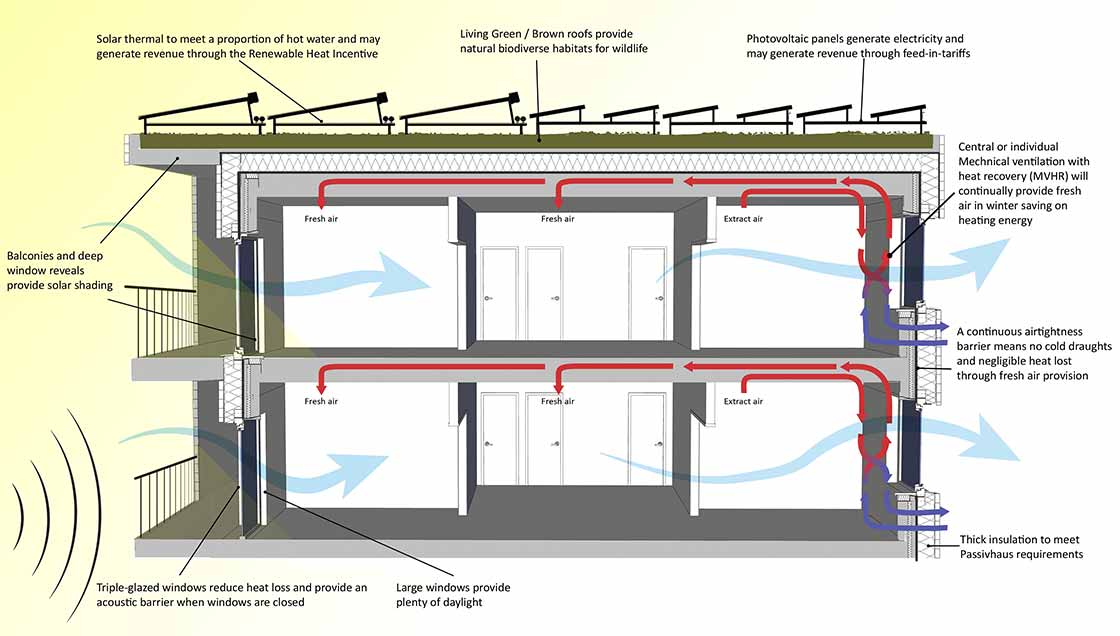

As the various options were explored, passive house became ever more popular, not least because it ticked a number of ancillary boxes. Agar Grove sits at the heart of the borough, close to Camden High Street and Kings Cross Station, and hemmed in by the aforementioned railway. So, it’s noisy. Triple glazing and whole house ventilation would probably be necessary regardless of design methodology.

Moreover, fuel poverty is a significant issue for many of the estate’s fixed income residents. There was also the simple fact that quality assurance is intrinsic to the passive house standard.

Liveable spaces

There were two central challenges on the site. The first relates to density. The existing site had 249 units, which works out at 97 homes per hectare. The new development, once completed, will have almost twice the number of units – 493. As one of the most accessible sites in the borough, and in the context of a wider housing crisis, it was considered necessary to bring housing density more in line with the surrounding area.

Understandably this was a sensitive issue for residents. The fact there was – in the end – general acceptance of the idea that everyone would be getting a lot of new neighbours gives you some idea of the level of trust that had been built up during the consultation phase.

If this was a difficult pill for the residents to swallow, the second challenge that the design team set itself did a lot to balance things out: to ensure tenants would only have to move once during the build process.

The phasing of the scheme means that a new block is built and, once complete, residents move in and the old block is demolished. This ‘single decant’ process has been the guiding force in the sequencing of the project.

This article was originally published in issue 31 of Passive House Plus magazine. Want immediate access to all back issues and exclusive extra content? Click here to subscribe for as little as €10, or click here to receive the next issue free of charge

“It’s quite a complex puzzle,” says Christensen, “because some families get smaller while others get bigger [during the build]. You’re giving everyone this promise early on and you’ve got to make sure you can keep it.”

It’s also worth noting that rather than put the development out to tender, Camden Council decided to take on the role of developer. While this model does involve the local authority taking on more risk, it facilitates the provision of a higher level of social housing. The planned breakdown is 50% affordable, 50% private, with the latter cross-subsidising the former.

The new Agar Grove masterplan is based upon the traditional concept of streets and squares, with an emphasis on buildings which have front doors at street level, creating liveable spaces between them, and allowing people to move across, through and within the site. The overarching desire is to create a place where people want to live, and which contributes positively to the surrounding area. Roadways within the estate are pedestrian and bike-friendly, while parking is only provided for existing cars and is to be phased out over time.

“The design has a logical network of streets that you can find your way around without getting lost,” says James Woodward. In most blocks you have street frontage to one side with shared residents’ gardens at the back. “There is now a legible hierarchy between those spaces.”

Achieving the desired layout for the site meant that it wasn’t always possible to orientate the dwellings southward for maximum solar gain, however.

“That’s been one of the tensions at the centre of the scheme,” he says. “I think if we had oriented everything in the same way, it wouldn’t have worked with the shape of the site and the context of the landscape.”

So, while some blocks have an ideal orientation, others do not. But while a southerly aspect lends itself to achieving the passive house standard in the simplest and most economical manner possible, it is technically possible to achieve the standard with any orientation. It can just mean compensating in other areas — like, for example, using more insulation.

By happy chance, the first phase of the project had the north-south orientation favoured by passive house designers. This, says Woodward, has meant that the lessons learned can be applied to subsequent phases, where the orientations will not be quite so favourable. To the same end, the project teams will hold a ‘lessons learned workshop’ at the end of each phase, providing feedback to the designers on which elements of their plans are most challenging to deliver in practice.

An illustration which succinctly sums up most of the key sustainability approaches adopted at Agar Grove

Phase one

Phase one at Agar Grove – now complete – involved the construction of a 38-unit passive certified apartment block, ranging between five and seven storeys high. This was built with a concrete frame with infill blockwork and a thermally broken masonry support system.

Ann-Marie Fallon and Robert White of sustainable design specialists Architype (recently worthy winners of the AJ100 Sustainable Architect of the Year) were appointed by the contractor, Hill Partnerships, as delivery architects on phase one. Fallon is also project lead on phase two, which is currently onsite.

The adopted nature of the design meant that several amendments had to be made at delivery.

At tender stage, Block A was specified to be masonry construction with a 300 mm cavity.

However more detailed analysis by Architype using PHPP, the passive house design software, concluded that this cavity could be reduced to 150 mm due to the optimised form factor of the block (very compact at 1.6).

“That was a significant optimisation of the design to revert to a more ‘industry accepted’ cavity width, and it typifies what we tried to do on the project,” says Fallon. Such forensic review and optimisation of PHPP requirements is important for enabling the development of passive house at scale, making it cheaper and easier to build.

For example, the walls on Block A have a U-value of 0.17, above the typical requirement criteria for passive house (0.15), but still comfortable and sufficient to meet the passive house standard when the building — with its optimum orientation and form factor — is taken as a whole.

Similarly, Fallon says that the original tender of intent had the airtightness layer on the inside of the wall construction, as would be the typical approach taken on passive house schemes in 2014 when the scheme was initially tendered.

“Moving that to the outside was another innovative move by the delivery team. This optimised the speed of the programme and also created a simpler airtightness layer.”

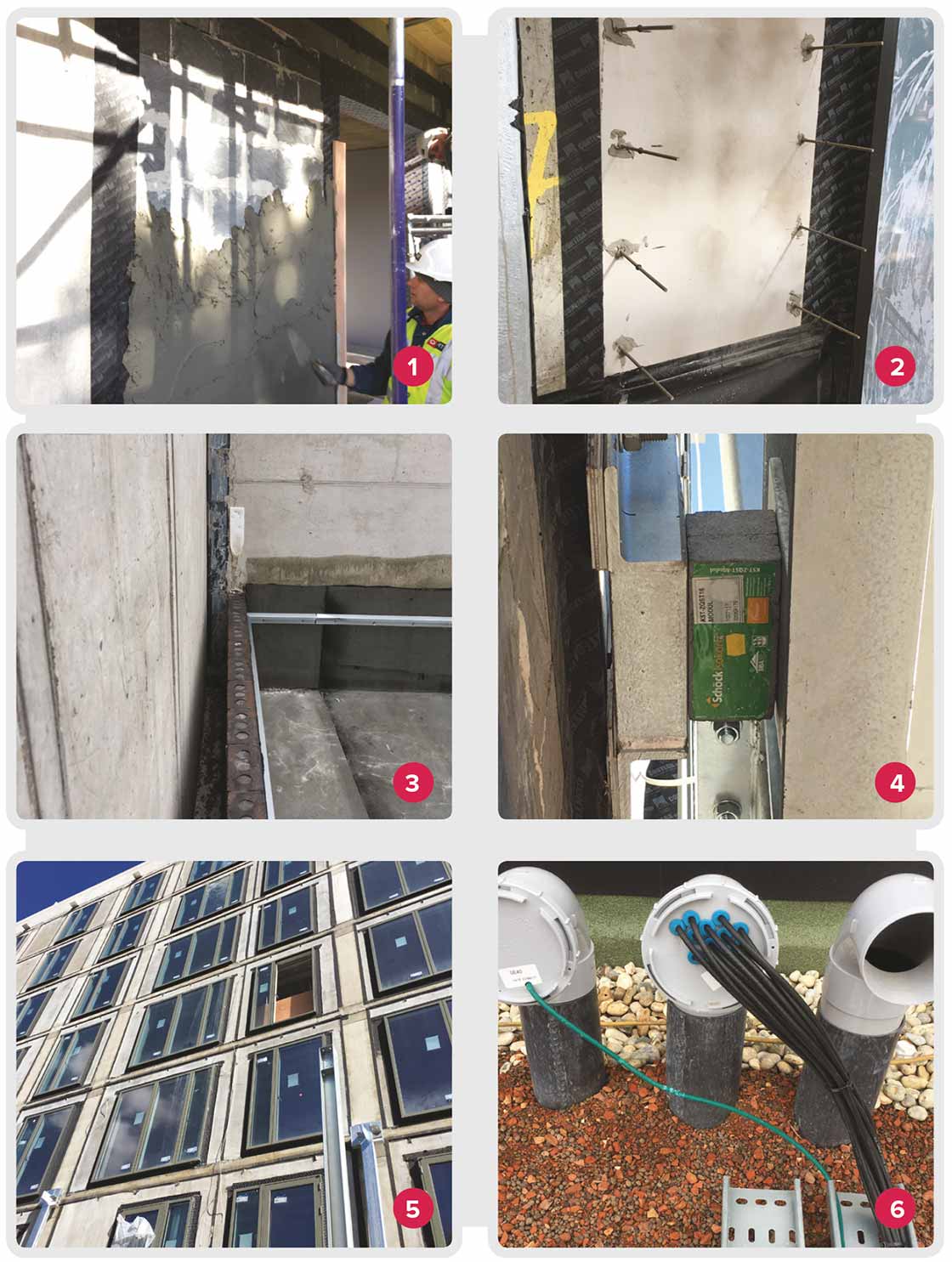

A wet plaster parge coat of 12-15 mm thickness was applied to the outer face of the inner leaf of blockwork. This was combined with what Fallon describes as a “robust taping strategy”.

In addition, the thermally broken TeploTie cavity ties were post-fixed using an anchor resin in pre-drilled holes. Masonry supports (over 500 in total) were carefully placed and co-ordinated to avoid tears in taping or large penetrations through the parge coat.

As Fallon asserts, keeping all of this to the outside meant that the airtightness strategy was kept independent of internal works within the envelope. These elements could progress in parallel without scheduling issues and with the added advantage of reducing the risk of accidental penetrations by subcontractors.

Which is not to say that subcontractors were kept out of the loop – far from it. Odran McShane of contractors Hill Partnerships says that subcontractor buy-in was a challenge at first, but ultimately a key factor in the success of the scheme. Once again, it all came back to communication.

“Passive house principles were not initially understood by subcontractors,” he says. “We took a number of steps to ensure the education of the workforce. This was achieved through inclusions within subcontractor orders, toolbox talks and physical samples of key airtightness details which were protected and maintained during the course of the build. The physical samples were particularly useful in that they provided a constant reference and benchmark for the subcontractor to refer back to.”

Thermal bridging was also a significant challenge on the scheme. Aside from the TeploTies deployed in the cavity, a thermally broken masonry support system was used on the concrete frame. There were over 500 of these supports in total.

1 A wet plaster parge coat was applied to the outer face of the inner leaf of blockwork as airtightness layer; 2 thermally broken TeploTie cavity ties, post-fixed using an anchor resin in pre-drilled holes, 3 Halfen HIT insulated connections and 4 Schoeck Isokorb connectors all help to minimise thermal bridging; 5 Installation of the Idealcombi Futura+ timber alu-clad triple-glazed windows; 6 airtightness seals at services pipe outlet.

“On a building of this scale, between brackets for hanging soffits, brickslips and so on, and the masonry supports themselves, there’s more complex design and installation challenges than you would experience with, say, your standard two-storey cavity wall house,” McShane says.

“It was a challenge to account for all of these junctions, however by considering these elements from the early stages of delivery they were part of the design considerations from the outset with the contractor and supplier.”

Embodied CO2

Fabric-first approaches like passive house may have largely done away with space heating loads, thereby drastically reducing operational energy use, but what about the energy used and carbon emitted in the construction of a building?

As Ann-Marie Fallon explains, a study was carried out on a block from the current phase of Agar Grove using Eccolab, Architype’s new carbon cost and energy tool, comparing the tendered construction methodology – cross laminated timber – with the concrete frame and masonry-based approach used on phase one.

The tendered design, if developed as a net zero carbon building with future 2050 de-carbonised electric emission factors applied to energy, has an almost 95% improvement on its total carbon emissions over a 60-year life.

This supports research elsewhere indicating that in 30 years’ time, the biggest carbon emissions in buildings will come from embodied rather than operational carbon emissions. “As designers we need to be assessing buildings in much more detail with this in mind for future life span adaptability,” says Fallon.

Summer comfort

PHPP determined an overheating risk of 6% for Block A (meaning the indoor temperature is expected to be above 25C for 6% of the year).

All very well in average summer conditions, but 2018 and 2019 were two of the hottest summers on record in London.

Fallon says that some changes to the glazing specification were implemented to mitigate the risk of overheating, such as a planning amendment to reduce glazing areas, and the careful application of g-value (solar gain value) changes, to east and west façades in particular. The large balcony that runs the length of the south façade is also critical to the shading strategy.

A post occupancy survey carried out by Camden found that 75% of residents were either comfortable or mostly comfortable during the summer months of 2018. During the last three weeks of July 2019, when temperatures in central London averaged 24C and reached a high of 38C during an extreme heatwave, average internal temperatures across three monitored units — each with blinds and windows in diff erent modes of operation — was 26C.

It is not believed that internal temperatures peaked any higher than 28C when external temperatures were 38C, but this is currently undergoing thorough review by Camden, and more detailed information will be available in future. The project team is currently assessing data from the previous 15 months, and Camden will continue monitoring for the next two years.

An important part of the overheating criteria being met alongside the above measures was the agreement with the certifier WARM on a robust summer ventilation strategy (cross ventilation and purging heat by opening windows at night). This was included and advised on in the home user guides circulated by Camden to all occupants. Subsequent phases of the scheme are now undergoing more detailed modelling of future performance and comfort under diff rent future climate warming scenarios, as now required by the Greater London Authority.

Fallon says in future it’s important that critical rooms in dwellings are modelled individually, in addition to the more general overheating analysis in PHPP — and stresses that sensible glazing ratios are always the best line of defence.

Provisional findings by Architype on behalf of Hill, who carried out the first 12 months of monitoring, found an average winter temperature of 22C, average humidity of 40% and very low CO2 levels. Findings presented by Architype at the London Future Build conference this year and at the Heidelberg Better Buildings conference suggests a 71% reduction in heating bills is possible for phase one residents (compared to 2018 Annual Fuel Poverty Statistics, see ‘In detail’ for more).

Camden are assessing the live metering data from the block currently to verify these findings for real.

Meanwhile, the UK Passivhaus Trust also recently completed a successful day of talks on Block A as a kick-off event for London Climate Action week at the start of July, giving perspectives and feedback from all the design and delivery stakeholders in the project.

Michelle Christensen says residents are very happy in their new homes. The fact that the council was dealing with an existing community from the very beginning meant that everyone had plenty of time to get used to the idea of passive house.

“We did home demonstrations when people moved in, and a week later we did some more. After each season, we knocked on doors and handed out questionnaires and did quite a bit of trouble-shooting, making sure people knew how best to use their home.”

“I’ve been in 95% of homes on the estate,” she says, “you get to know people, and they know who to call if they have issues. It took a while to earn that trust, but having it makes a huge difference to everyone.”

Selected project details

Main client: London Borough of Camden

Client: Hill Partnerships Ltd (in D&B contract with main client)

Design architects: Hawkins Brown

Delivery architects: Architype

Engineers: Stantec (formerly Peter Brett Associates)

Quantity surveyors: Arcadis

Passive house design: Architype

Passive house consultants: Max Fordham

Passive house site support: Enhabit

Passive house assessment: WARM

Airtightness testing: Enhabit/Paul Jennings

Energy rating assessment: NRG Consultants

M&E engineering contractor: Mark Robinson Associates

M&E engineering consultant: Max Fordham

Cavity insulation: Knauf

Service cavity insulation: Isover

Additional wall insulation: Kingspan

Foundation system: Jablite

Windows: Idealcombi

Doors & curtain walling: Schueco

Fire-rated internal doors: Premier SSL

Roof windows: LAMILUX UK Ltd

Airtightness products (tapes and membranes): Ecological Building Systems

Airtightness products (parge coat): Tarmac Building Products

Cavity wall ties: Ancon

Thermal breaks: Halfen, Schoeck, Armatherm

Brick slips: Eurobrick

Masonry supports: ACS

AAC blocks: Forterra

Fixings (soffits and walkways): Nvelope

PV Panels: Ample Energy

Heat recovery ventilation systems: Zehnder / Swegon

Heating system design: SAV

Heating & ventilation system installation: Morgan Cass

Heat recovery ventilation (design): Mark Robinson Associates

Solar shading: Contrasol

In detail

Building type (Block A): 38-unit, seven-storey residential block. Concrete frame & infill blockwork cavity wall construction.

Location: Agar Grove, Camden, London

Completion date: April 2018

Budget: Not disclosed

Passive house certification: Certified (Block A certified as one building)

Space heating demand (PHPP): 13 kWh/m2/yr

Heat load (PHPP): 9 W/m2

Primary energy demand (PHPP): 118 kWh/m2/yr

Heat loss form factor (PHPP): 1.6

Overheating (PHPP): 6%

Environmental assessment method: Code for Sustainable Homes L4

Airtightness (at 50 Pascals): 0.6 ACH on certificate, 0.59 ACH reported final test

Energy performance certificate (EPC): B 83 kWh/m2/yr

Thermal bridging: Concrete frame with infill 200 mm AAC blockwork cavity wall using Ancon TeploTies, thermally broken masonry support system and series of thermal breaks within junctions on concrete frame. Thermal bridges in their totality make up 66% of the heat loss of the scheme. The optimised form, large scale multi-unit high-density approach, and good site placement for orientation compensates for this.

Thermal breaks: Armatherm FRR thermal break pads, Halfen HIT insulated connections, Schoeck Isokorb connectors, TeploTie cavity wall ties, Thermalite blocks.

Energy bills (measured or estimated): Projected average annual gas bill of £162 per year per unit (£47 p/a for space heating, £115 for domestic hot water), including standing charges & VAT (for 4,000 kWh per year for space & water heating, as per PHPP). This is approximately a 71% reduction on average relative to the reference 50-69 sqm apartment in the 2018 Annual Fuel Poverty Statistics (£560 for 13,793 kWh/m2/yr).

Ground floor: 150 mm compacted base followed above by 50 mm sand blinding, 250 mm concrete slab, RIW Gas Seal Blue DPM, 135 mm Jablite classic EPS, 75 mm screed, varies floor finishes. U-value: 0.25W/m2k.

Walls: External leaf of, variously, brick or P-clad brick slip or followed inside by 150 mm cavity fully filled with Knauf Supafil insulation (includes height waiver for installation), 200 mm Thermalite Hi strength 7kN AAC block work with 10-15 mm parge coat to outer face as airtightness layer, internal stud lining (thickness varies). U-value: 0.165W/m2k.

Roof: Bauder extensive biodiverse/brown seed roof with Flora 3 seed mix (mix of sedum and plug plants suitable for an urban living roof as per planning requirements). Bauder PIR insulation under growing medium varying from 140 mm to 270 mm thickness for drainage and falls and sitting on vapour control membrane and 250 mm concrete slab. U Value: 0.09W/m2k.

Windows & external doors: Idealcombi Futura + timber alu-clad range for domestic doors and windows, g-value modifications to windows to mitigate overheating risk where required. Reference overall U-value: 0.74 W/ m2k (European test size). Schueco communal entrance doors. Premier SSL fire doors for FD60 and FD90.

Roof windows: LAMILUX F100 smoke lift glass skylights. Overall U-value: 1.0 W/m2k for reference size.

Heating system: Communal heating system. 5 x Broag Remeha Quinta PRO gas boilers arranged in cascade feeding individual, insulated Danfoss Flatstation heat interface units (HIUs) in each apartment with fully insulated manifolds, pipework and connections. No hot water storage in dwellings, the HIUs provide a heat boost as demanded. Heating distribution per flat consists of 1 x radiator in the living room and 1 x towel radiator in the bathroom.

Ventilation: 28 units ventilated by centralised MVHR system (2 Swegon Gold RX units). Individual maisonettes on the ground floor ventilated by individual Zehnder Comfoair Q350 units.

Water: Restricted waterflow taps to satisfy Part G of the Building Regulations.

Image gallery

-

1423_N41651

1423_N41651

1423_N41651

1423_N41651

-

Agar-Grove-environmental-principles

Agar-Grove-environmental-principles

Agar-Grove-environmental-principles

Agar-Grove-environmental-principles

-

DD-152_Z9

DD-152_Z9

DD-152_Z9

DD-152_Z9

-

DD-501_Z4

DD-501_Z4

DD-501_Z4

DD-501_Z4

-

DD-503_Z7

DD-503_Z7

DD-503_Z7

DD-503_Z7

-

DD-513_Z4

DD-513_Z4

DD-513_Z4

DD-513_Z4

-

Flat-6-winter-monitoring-block

Flat-6-winter-monitoring-block

Flat-6-winter-monitoring-block

Flat-6-winter-monitoring-block

-

North-West-and-East-elevations

North-West-and-East-elevations

North-West-and-East-elevations

North-West-and-East-elevations

-

Typical-window-jamb

Typical-window-jamb

Typical-window-jamb

Typical-window-jamb

https://passivehouseplus.ie/magazine/new-build/big-time-uk-s-largest-passive-scheme-comes-to-camden#sigProId2f5dace63a