- Blogs

- Posted

Top 5 questions about specifying structural thermal breaks

Read Farrat's guide to specifying structural thermal breaks

Written and sponsored by structural thermal break manufacturer Farrat.

The ability to transmit structural loads whilst addressing thermal performance through a building envelope has long been a difficult balance for building designers. The weight of decision has often fallen on the side of the structure, with the importance of structural integrity winning out against the impact of structural members piercing the thermal envelope.

However, as energy requirements for new and retrofitted buildings have tightened, so has the need to minimise thermal bridging. This has resulted in greater levels of insulation in planar elements of a building envelope, leading to more noticeable and detrimental effects of those ‘hard to treat’ details such as structural penetrations. Add to this the need to achieve compliant critical internal temperature factors for the avoidance of unsightly or harmful mould growth, and mitigating thermal bridges in a building envelope moves higher up the list of problems to solve.

Equally, the growing influence of fire design on structures has also led to the requirement for enhanced fire performance criteria for materials in the building envelope. To address this imbalance, new building materials and methods of thermally breaking structural connections, such as steel beams and balcony connections, have been developed. In the below guide, we address the most frequent questions asked by architects and building envelope specialists when specifying Farrat Structural Thermal Breaks.

Which Farrat Structural Thermal Break material should I specify?

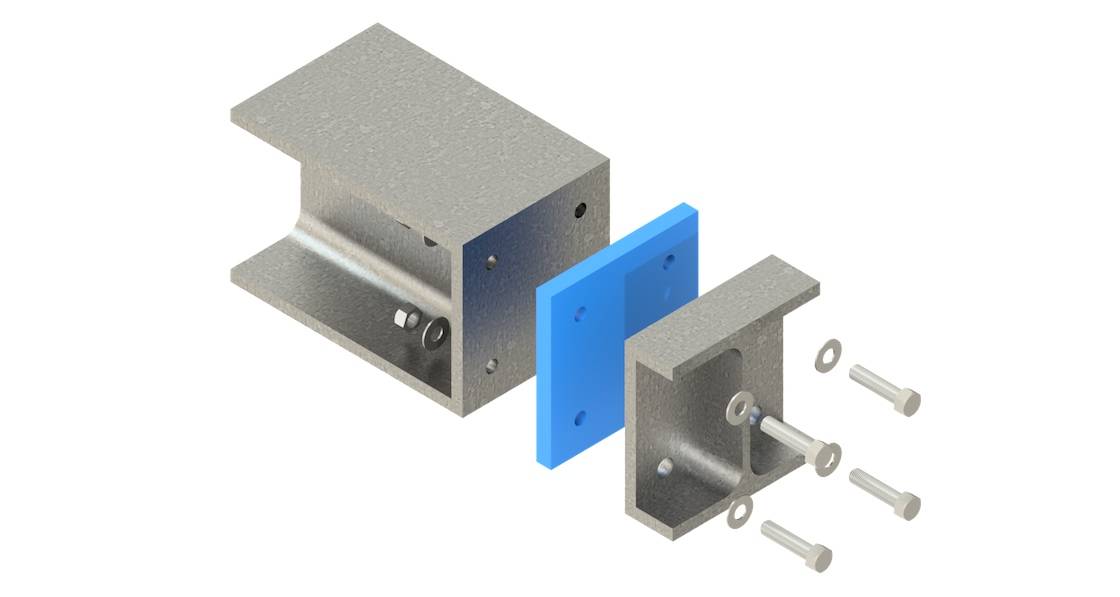

Farrat Structural Thermal Breaks take the form of flat plates of any dimensions, which provide architects with complete design freedom, and structural engineers with the capability to design to standard codes, with a simple configuration. Farrat offer three independently tested structural thermal break materials, which are designed to balance high structural performance and low thermal conductivity.

Farrat TBK is most specified across typical connection details, with high compressive strength (312MPa fck) and the best thermal performance in the range (0.187 W/mK). Farrat TBF is the optimum material when fire performance is a consideration, such as within high-rise buildings, due to its high compressive strength (355MPa fck) and low thermal conductivity (0.2 W/mK) performance characteristics, supported by an A2, s1,d0 Non-Combustible Classification. Farrat TBL is the favourable material when structural loadings and requirements for thermal performance are lower, and budgets are constrained, offering medium compressive strength (89MPa fck) and thermal conductivity (0.292 W/mK) performance characteristics.

Farrat advise that design professionals always validate that thermal break materials are independently tested and certified with an appropriate safety factor that has been applied to characteristic performance values, to determine the design load (fcd). Full material characteristics and performance specifications for each Farrat material are available on the company's architects' portal.

What thickness of thermal break should I specify?

Farrat Structural Thermal Breaks come in a range of thicknesses from 5 mm to 25 mm. The only way to accurately calculate the thickness of a structural thermal break is to carry out finite element analysis on the connection and its allied components. This is not common practice due to the relative rarity of details requiring structural thermal breaks and the time and cost of carrying out the thermal modelling.

However, it is possible to understand from typical example the effects of thickness of plates on example connection. Farrat illustrate this for their products using BRE (Building Research Establishment) certified thermal models, which show that despite achieving a lower thermal performance than the surrounding building fabric, it is possible to remove the negative effects of a cold bridge with a minimal amount of insulating material (typically a 15mm to 25mm thickness). Plates may be used in multiples, but 25 mm will mitigate most thermal bridge issues for dwellings and commercial office building details.

Do structural thermal breaks need to be as thick as the surrounding wall insulation?

The primary determinate for the thickness of a structural thermal break is its effect in achieving a satisfactory critical internal temperature factor on the warm side of the structural connection. It is not necessary for the structural thermal break thickness to match the surrounding wall insulation thickness to be a success/ Since the thermal break is required to be a structural element, it will always be a relative weak point as an insulant. However, as illustrated in Farrat’s latest passive house certified details, this still makes it possible to achieve the highest of building performance standards.

Will the structural thermal break meet my U-value requirements?

U-value calculations are the simple method of understanding the thermal performance of a build-up of construction materials in a flat plane (planar). Structural thermal breaks are typically used to solve problems in ‘point’ structural connections or in some case linear connections. As such their performance cannot be calculated using the U value method of calculation and requires a Psi or Chi value calculation to be undertaken.

These calculations can only be undertaken using 2D or 3D finite element analysis (FEA) modelling. As this is currently not common practice, Farrat utilise their typical BRE certified thermal models, to provide indicative Psi and Chi values for common structural connections to allow simplified specification of structural thermal breaks, where calculation models have not been created.

Farrat TBF is a structural thermal break desigend to maintain structural integrity in the event of a fire

Do structural thermal breaks need to be non-combustible?

The use of non-combustible materials, particularly in high rise buildings has become more common place in recent years due, in part, to high profile building fires and subsequent investigations. Structural thermal breaks are extensively used as part of the structural support in facade systems or as the main structural connection in balconies. These elements are key to the performance of the building envelope in the case of fire and the avoidance of catastrophic failure and collapse.

Farrat TBF is a A2,s1,d0 non-combustible structural thermal break material that is capable of withstanding 1000 C heat and maintains its structural integrity in the event of fire. Different building types and legislators have differing technical and regulatory requirements for fire design, but if fire is a concern that requires addressing, then the use of non-combustible thermal breaks is one way to mitigate that risk.

For more information and guidance on specifying structural thermal breaks please contact Farrat. Farrat are specialists in thermal, acoustic, and structural isolation within the building construction industry.

With over 60 years’ experience in the design and manufacture of building construction solutions, Farrat’s niche knowledge of materials science and building physics has been at the heart of the development of Structural Thermal Breaks that can deliver consistent and safe structural performance, whilst minimising the impact of thermal bridges.

Visit: www.farrat.com

Contact: This email address is being protected from spambots. You need JavaScript enabled to view it.

Follow on: Twitter, Instagram and LinkedIn

- Thermal breaks

- structural thermal breaks

- insulation

- building envelope

- farrat

- Irish Marketplace

- UK Marketplace

Related items

-

New Ejot profile cuts thermal bridging losses by 25mm insulation equivalent

New Ejot profile cuts thermal bridging losses by 25mm insulation equivalent -

Build Homes Better updates Isoquick certification to tackle brick support challenge

Build Homes Better updates Isoquick certification to tackle brick support challenge -

Ecological Building Systems expands UK and Irish straw panel construction with EcoCocon deal

Ecological Building Systems expands UK and Irish straw panel construction with EcoCocon deal -

Focus on better buildings, not better spreadsheets

Focus on better buildings, not better spreadsheets -

MBC offers total passive house envelope solutions

MBC offers total passive house envelope solutions -

Grant’s Aerona R290: A next-gen heat pump designed for the Irish climate

Grant’s Aerona R290: A next-gen heat pump designed for the Irish climate