- Renewable Energy

- Posted

Peak coal

In recent years it’s become increasingly accepted that the age of cheap and abundant oil and gas supplies is coming to an end, and that future energy needs will have to be met from cleaner, more widely available fuel sources. According to Richard Douthwaite, the prospects of exponentially rising costs and failure to ramp up carbon capture and storage will mitigate against coal’s ability to take up the slack.

As supplies of oil and natural gas are expected to decline over the next 25 years, the thoughts of electricity generators throughout the world are increasingly turning to coal. According to estimates from the Natural Resources Defense Council in the US, the CO2 emissions from all the coal-fired power plants built or planned since 2000 will total 660 billion tonnes over the next 25 years.

This is alarming since the figure is about 25 per cent greater than the total emissions from all the coal burned in the world, from the dawn of the industrial revolution up to the end of 1999. Consequently, if the plants still at the planning stage actually get built, the only way that they can be used without hastening the start of a catastrophic change in the world's climate would be for their emissions to be captured and stored underground.

The world's most senior climate civil servant, Yvo de Boer, the executive secretary of the United Nations Framework Convention on Climate Change, thinks this is possible. In a speech in March at OPEC's 4th international seminar on petroleum in Vienna he said: “The Intergovernmental Panel on Climate Change has identified carbon dioxide capture and storage (CCS) as one of the most promising technologies for the rapid reduction of global emissions.”

He continued: “CCS pilot projects are promising. The oldest project off the coast of Norway has been running for 13 years without any sign of CO2 leakage. Last year, the Swedish utility Vattenfall opened the first power plant to incorporate CCS in Germany. Several other firms hope to start similar pilot projects this year. OPEC's initiative to establish a CCS research and development fund is encouraging. Last year, the European Union passed a law requiring its members to draw up rules and regulations for CCS.”

Note how de Boer used the word “promising” twice. That's because he could not say anything more definite about CCS as it is still years away from being ready for full-scale commercial use. The Vattenfall CCS plant he mentioned only involves a 30MW boiler that burns lignite in pure oxygen. This produces steam and CO2. The steam is condensed to leave 99.7 per cent pure CO2. "The plant captures nine tonnes of CO2 per hour at full load," Staffan Gortz, a Vattenfall spokesman, says. “We don't have a storage site yet." About five per cent of the CO2 in the lignite escapes.

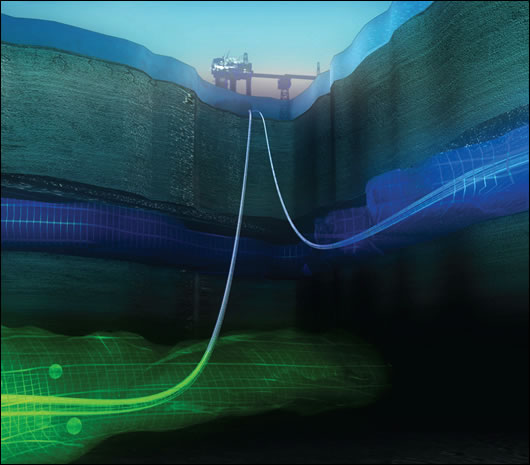

The Norwegian project de Boer mentioned separates CO2 from the natural gas coming from Statoil's Sleipner gas field and injects it back into the permeable rock beneath the seabed. As this avoids the release of over one million tonnes of CO2 per year, the project is well worthwhile but all it proves is that pumping CO2 back underground is feasible and that the gas doesn't seem to leak.

These two projects provide almost the entire foundation for a key component of the EU's energy and climate policy. "We have to continue to be able to exploit fossil fuels as a key source of energy for decades to come,” commission president José Manuel Barroso said in January last year. “But this risks ballooning global emissions by mid-century. So we need to make CCS the norm for new power plants, and to set up twelve demonstration plants by 2015.” The possibility that Ireland should try to get funding for one of these demonstration plants is being discussed.

Until CCS technology is proven, all new coal-fired power plants built within the EU are likely to be required to be “capture-ready” so that they can be fitted with CCS equipment when, as the International Energy Agency puts it “the necessary regulatory or economic drivers are in place.” For example, it is promised that the power station proposed to replace the old one at Kingsnorth in Kent will be built this way if the go-ahead is given. Objectors point out that no-one has any idea if and when the technology will be ready and that until it is, the new Kingsnorth (if built) will pump out around 8m tonnes of CO2 per year, an amount equivalent to the total annual CO2 emissions of Ghana.

Yvo de Boer, the executive secretary of the United Nations Framework Convention on Climate Change has said that carbon capture and storage is a ‘promising’ technology, but hasn’t been able to promote it as a viable solution in the short term.

In Ireland, the ESB's plans for Moneypoint, which currently emits 5.6m tonnes of CO2 a year, just over a third of the ESB's total, involve fitting it with CCS equipment when the plant has to be re-built some time between 2025 and 2030.

So how sensible is it for the EU and for Ireland to adopt this policy of putting so many energy eggs into the untried coal-plus-CCS basket? Let's explore this step by step.

First – is there enough coal?

Until recently, almost everyone believed that there was enough coal to power the world economy for generations to come. After all, when the 2006 rate of consumption, 5.9bn tonnes per year, was compared with the best estimate for the world's coal resource, 850bn tonnes, there appeared to be 144 years' supply of coal left. But that calculation ignored the fact that the rate at which the world has been using coal has been increasing exponentially. Between 1930 and 2000, consumption grew at an average of two per cent a year. If that rate continued and reserves really were 850bn tonnes, all the coal would be gone by 2074. But between 1997 and 2006, coal consumption went up by 3.4 per cent per year. If that rate applies, there is only 49 years of coal left.

But how reliable is that 850bn tonne figure, which comes from the World Energy Council? The answer is – not at all. As recently as 2000, it was estimated that reserves were almost twice as large and that, as a result, production could continue at the then-current rate for 277 years. The sharp fall in the reserve figure came about when some national governments – Britain, Germany and Poland among them - made cuts of up to 90 per cent in their estimates of how much coal their countries had left to produce. Significantly, however, two large coal producers, Russia and China, have not cut their reserve estimates since 1996 and 1990 respectively despite massive production since then.

Ignoring reserve estimates, Professor David Rutledge, the chair of the engineering and applied science department at the California Institute of Technology, has used actual production figures to suggest that only about 400bn tonnes of coal might still be recoverable. He employed the same technique as that used by M. King Hubbert in 1956 to predict that US oil production would peak in 1970. It peaked in 1971.

Rutledge won't say when he expects the world's production of coal to peak. However, Mikael Höök and his colleagues at Uppsala University in Sweden who have taken a similar approach to Rutledge's think that the peak will occur by 2020. A 30-year-long plateau will follow before the decline begins.

The Uppsala estimate corresponds quite closely with that of the Energy Watch Group in Germany which forecast in 2007 that global coal production would peak around 2025 at 30 per cent above present production “in the best case”. In other words, the peak might occur earlier, and at a lower output level. The group's figures are based on country-by-country assessments. The group will publish a revised assessment this autumn.

90 per cent of global coal reserves are concentrated in just six countries – the US, Russia, India, China, Australia, and South Africa. The US alone holds 30 per cent of all reserves and is the second largest producer. China is by far the largest producer but only has reserves half the size of those in the US. It is significant that both countries are already having problems getting an adequate supply.

The first power plant to incorporate CCS was opened in Germany last year by Swedish utility Vattenfall

In the US, for example, bituminous coal production peaked in 1990 and is now falling. Another indicator of production difficulties is the fact that the number of tonnes produced per miner per month, which was steadily increasing until 2000, has declined since then. In addition, the country has switched from being a net exporter of steam coal to a net importer.

China is also having to import increasing amounts of coal. Despite the economic slowdown it imported 5.72m tonnes of coal in March this year, up 37.4 per cent on a year earlier. The Energy Watch Group expects China's domestic output to peak around 2015. “The steep rise in production of the past few years must be followed by a steep decline after 2020.” it says. The ambitious plans the country had to build several plants to convert coal to liquid fuel have been cancelled.

It therefore seems a highly risky strategy for any country to plan to rely on coal for a significant part of its energy supply beyond 2020, and, since power stations take, say, five years to build and then have a 25-30 year life, it might be unwise to build more. Whatever happens, coal will not be cheap. Its price is closely linked with that of oil. Over the past five years, if the graphs showing the price movements of the two fuels haven't been labelled, it's been hard to tell them apart.

Second – what proportion of emissions will CCS actually capture?

Although the EU has decided that all new coal power plants will have to be fitted with CCS equipment after 2020, the technology may not be ready by then. According to the World Business Council on Sustainable Development in 2006 "Commercial implementation is not expected for another 20 years." This means that the technique is likely to come into use just as the global production of coal peaks and after the last date – 2020 – on which the latest, rather optimistic, calculations show that global emissions must peak if there is to be a good chance of restricting global warming to 2o above the pre-industrial level. In any case, many scientists believe that the 2o maximum is much too high.

The three main technologies proposed for CCS are set out in the panel. Whichever is used, the process takes a lot of power – somewhere between 20 and 44 per cent of a station's output. In other words, for every three power stations now in use we'd need at least another one just to maintain the present electrical supply.

Not only would that extra power station burn more coal, it would also require additional energy to be invested in building it and in developing the mine and transport system to provide its fuel supply. And, of course, the mining process itself takes energy and involves the release of greenhouse emissions, particularly methane, which is a much more climate-damaging gas than CO2. As a result, a Wuppertal Institute study concluded that, if it was assumed that the CCS system captured 90 per cent of a station's emissions, the real reduction in emissions would be somewhere between 67 and 78 per cent because of increased emissions elsewhere. As coal gets scarcer and more effort is required to mine it, the proportion of uncaptured emissions can only get worse.

The extra energy and capital equipment required for CCS make it costly. The US Department of Energy estimated in May 2007 that electricity from a new power plant burning pulverised coal and capturing 90 per cent of the CO2 with amine scrubbers would cost 80 per cent more than power from an identical plant without CO2 capture. Power from a plant in which coal was turned to gas before being burned would cost 63 per cent more. These increases in cost would make coal-fired electricity uncompetitive with that from other power sources. As a result, companies building “capture-ready” coal-fired plants now can be expected to fight tooth and nail against actually having to install and use the CCS equipment.

An illustration conveying the simultaneous extraction of natural gas (in green) and insertion of carbon dioxide (in blue) at Statoil's Sleipner West field in the Norwegian North Sea

Third – should the world be investing in coal power at all?

Is investing a lot of energy to build a power station and provide its fuel supply the most effective way that the world can solve its energy-supply problem? What evidence there is seems to suggest that it is not. Luc Gagnon of Quebec Hydro calculates that for every unit of energy invested in developing a gasifying coal-burning power station and supplying it with fuel, up to seven units of energy can be expected back. However, if CCS is used, the energy return falls to only 3.3 times. This is only a tenth of the return that can be expected from onshore wind and half what is currently available from photovoltaics. In the Irish case, equipping windfarms with storage capacity would give a very much better return.

And what happens when the new generation of coal-burning stations reaches the end of their lives in 2035 or 2040? There will be no question of building new ones – the coal will have gone. A switch will have to be made to wind, solar, biomass, wave or tide but there will be much less energy available to invest in the infrastructure and capital equipment required than there is now. Consequently, opting to invest energy in building and supplying another round of coal-fired power stations now can only be justified if there is a reasonable expectation that renewable energy technologies will advance so rapidly in the next 30 years that:

1. The total amount of energy required to build and supply the CCS equipped coal plant and then, when it closes, adopt a renewable technology is less than it would be to invest in a renewable technology now and then replace or renew it at the end of its working life, and,

2. The total CO2 emissions of the CCS route to renewables is less than from adopting renewables now.

It is hard to see how either condition could ever be met.

Four - what plans does Ireland have for adopting CCS?

The National Climate Change Strategy 2007-2012 says that “the potential for the use of carbon capture and storage, whether in new plant or by way of refitting existing plant, will be pursued in the period to 2020.” In line with this, SEI, the EPA and the Geological Survey of Northern Ireland jointly commissioned a report on “The Potential for Geological Storage of CO2 for the Island of Ireland.” This was published last September. It proposes that major emitters of CO2 be concentrated in three areas – the Shannon Basin around Moneypoint, Cork and Belfast. Emissions from the Cork and Shannon concentrations – which would include those from the Platin cement plant and Auginish Alumina - would be liquefied and piped for disposal in the Kinsale Head gas field. Those from Belfast would go to a site in the Portpatrick Basin.

According to the report, the combined cost of developing the CCS facility at Moneypoint, the 235km pipeline, 50km of which would be under the sea, and the storage site at Kinsale is put at about e3bn. Over the 25 year lifetime of the plant, it is estimated that this would add 50 – 60 per cent to the cost of the power. Looked at another way, it would cost between e31 and e47 for each tonne of CO2 that was tucked safely away.

The report claims that despite a possible 60 per cent increase, the cost of the power would still be less than the current incentive price being offered for offshore wind but more than that for onshore wind power.

Kingsnorth, a dual-fired coal and oil power station, in Kent, England

The Kinsale field is estimated to have the potential to store up to 330m tonnes of CO2. As the Cork and Shannon plants that would be fitted with CCS equipment released 11.5m tonnes of the gas in 2007 and their emissions could be expected to increase, it would be adequate for less than 30 years. Far less, in fact, as the new Moneypoint station is envisaged as having 900MW capacity – enough to supply about 15 per cent of the all-Ireland power demand – and it would need additional energy to run its CCS equipment. In addition, the new gas-fired power stations at Aghada and Whitegate would be connected up too.

In short, Kinsale would not last the life of the Moneypoint plant and it would be necessary to find another disposal site. The Clare Basin, which is close to Moneypoint, is being considered but the report says it would require a costly research programme to prove its potential and there is a high risk it might not be suitable.

Energy minister Eamon Ryan's comment on the launch of the CCS report was remarkably cool: “This initial study has indicated that carbon capture and storage may become a viable option for Ireland in the medium term, but considerably more analysis is still required.” He's right to be sceptical. Over the past few centuries, whenever humanity has run into an environmental or resource constraint, we've opted to solve the problem by throwing more energy at it.

Take the history of coal itself. As the demand for coal increased, the easiest, shallowest mines were soon exhausted, and deeper and deeper pits had to be dug. This posed enormous problems since, if a shaft is sunk below the water table, it floods and a pump has to be installed to keep things reasonably dry. The early pumps consisted of rags or buckets on continuous chains which were turned by horses or, if a stream was handy, a water wheel. However, the deeper a shaft went, the longer the chain had to be and the more friction the horse or the wheel had to overcome. As this placed a real limit on how deep a mine could go, mine-owners were keen to find other ways of powering their pumps. Eventually, coal-fired steam power began to be used for pumping water out of mines. In a somewhat incestuous way, coal energy was being used for mining coal.

Now, at a time when more and more of the energy in every lump of coal is required to mine and deliver the next lump, we want to use some of the remaining coal energy so that we can burn more coal without causing an environmental catastrophe.

With fossil fuel, we are running into rapidly diminishing returns. Sooner or later, we've got to decide that those returns are unacceptable and that we either find a way of living using less energy or come up with another, more energy-efficient way of supplying our energy needs. Wind, plus storage, is already such a way. As Gagnon's figures show, biomass is another. Others will soon emerge.

Consequently, rather than spend e3bn on a project with a 25-year life which will leave us unprepared for a low-carbon-energy future, the resources involved should be used to develop renewable energy sources. The ESB should resign itself to closing Moneypoint at the end of the current equipment's life and find other ways to supply 15 per cent of the island's electrical power. Possible ways of capturing the carbon

Oxyfuel combustion, the method being used in Germany by Vattenfall, burns fossil fuels in 95 per cent pure oxygen instead of air. This results in a flue gas with high CO2 concentrations that can be compressed for transport and storage.

This bar-chart shows the amount of electrical energy that can be expected to be delivered over the life of a project in return for investing one unit of energy to build the plant and, if required, supply it with fuel. Of the technologies compared, hydro-electricity gives much the best return. Source: Luc Gagnon, senior advisor, climate change, Hydro-Québec.

Pre-combustion capture systems remove CO2 before combustion by gasifying the fossil fuel. This produces a mix of carbon monoxide, methane and hydrogen which is then reacted with steam. The carbon in the methane and in the carbon monoxide grabs the oxygen atom from the steam (H2O) to leave just hydrogen and CO2. The CO2 is separated out and the hydrogen is burned. China and Australia are building plants which use this technique.

Post-combustion techniques treat power station flue gas. Flue gas typically contains up to 14 per cent CO2, which can be separated out by chemical or physical absorption, cryogenics or the use of membranes. Chemical absorption with amines is currently preferred. Once recovered, the CO2 is cooled, dried and compressed for transport. Existing coal power stations will have to use this post-combustion technique but it is costly to install - perhaps $1600/kWe – and takes a lot of energy to operate. One estimate is that it would reduce the output of an existing 500MW subcritical pulverized coal power plant by over 40 per cent to 294MW.

Possible ways of capturing the carbon

Oxyfuel combustion, the method being used in Germany by Vattenfall, burns fossil fuels in 95 per cent pure oxygen instead of air. This results in a flue gas with high CO2 concentrations that can be compressed for transport and storage.

Pre-combustion capture systems remove CO2 before combustion by gasifying the fossil fuel. This produces a mix of carbon monoxide, methane and hydrogen which is then reacted with steam. The carbon in the methane and in the carbon monoxide grabs the oxygen atom from the steam (H2O) to leave just hydrogen and CO2. The CO2 is separated out and the hydrogen is burned. China and Australia are building plants which use this technique.

Post-combustion techniques treat power station flue gas. Flue gas typically contains up to 14 per cent CO2, which can be separated out by chemical or physical absorption, cryogenics or the use of membranes. Chemical absorption with amines is currently preferred. Once recovered, the CO2 is cooled, dried and compressed for transport. Existing coal power stations will have to use this post-combustion technique but it is costly to install - perhaps $1600/kWe – and takes a lot of energy to operate. One estimate is that it would reduce the output of an existing 500MW subcritical pulverized coal power plant by over 40 per cent to 294MW.

- Articles

- renewable energy

- Peak coal

- Feasta

- oil

- gas

- energy needs

- carbon capture

- fossil fuels

- oxyfuel

- membranes

Related items

-

Partel launches paper-based membranes

Partel launches paper-based membranes -

Partel obtains EPDs for airtight membranes

Partel obtains EPDs for airtight membranes -

EU proposes gas demand reduction plan till spring

EU proposes gas demand reduction plan till spring -

The world energy crisis 2022

The world energy crisis 2022 -

Partel launches new Acraline Roll adhesive

Partel launches new Acraline Roll adhesive -

How do breather membranes work?

How do breather membranes work? -

Grant invests in biofuel tech for oil boilers

Grant invests in biofuel tech for oil boilers -

Oil heating sector pivots to biofuels, but green groups raise concern

Oil heating sector pivots to biofuels, but green groups raise concern -

Architects call for urgent climate action ahead of COP 26

Architects call for urgent climate action ahead of COP 26 -

Partel’s Izoperm Plus achieves passive house ‘A’ cert

Partel’s Izoperm Plus achieves passive house ‘A’ cert -

Liquid membranes transforming airtightness work — Blowerproof UK

Liquid membranes transforming airtightness work — Blowerproof UK -

Partel launches new fire-rated breather membrane

Partel launches new fire-rated breather membrane