- Climate Change

- Posted

Intensive care

The emergence of climate change as a serious concern has helped create a burgeoning market for a vast range of eco technologies. All too often, however, the basic principles of sustainable design are ignored or misunderstood. Chris Croly of mechanical and electrical engineers Building Design Partnership describes the detail of a building which reveals a no-nonsense attention to sustainability.

The new Nurses Education Building for Waterford Institute of Technology was recently awarded the Department of the Environment, Heritage and Local Government Sustainable Building Award 2007 and the title of Best Sustainable Project in the 2007 RIAI awards. In their discussion of the project, the RIAI judges concluded: "It wears the serious effort of integrating its multifunctional sustainable programme well and its lightness appears deceptively easy and simple."

That observation cuts straight to the heart of the building’s beauty. Deceptive simplicity is the key to producing a cost effective, healthy, and low energy building and is often missed amongst the many buzzwords of expensive equipment that can be attached to a building to give it an instant appearance of sustainable merit. It is often both more effective and challenging to make buildings simple than to add complex technologies to an energy hungry building concept.

If the building does not have the immediate outward appearance of a carefully crafted sustainable design how does it demonstrate its right to be counted amongst Irelands lowest energy buildings? One of the most important metrics of a building is its proven energy usage through monitoring and this building has been monitored for a full year of operation providing a performance of 65kWh/m2/yr for heating, hot water and electrical energy use which is better than half the good practice figure of 167 kWh/m2/yr stated in CIBSE guide F for this building type.

Waterford Institute of Technology is committed to a program of procuring sustainable buildings and the Nurses Education Building is the latest in a series of low energy buildings constructed on the campus.

This latest addition has been achieved under normal budget constraints and in this context the building has some important lessons to offer. It is also clear that the building’s architectural and functional performance has not been compromised while addressing the project’s sustainability targets and this stunning building offers an exciting and healthy learning environment for its staff and students.

The building contains a large multi-functional atrium space, two large lecture theatres, specialist nursing training rooms, and a number of general lecture and office spaces.

Natural cooling

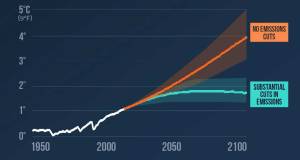

As Ireland’s temperatures rise, some clients are concerned that naturally ventilated buildings may not be able to maintain comfort conditions throughout their lifetime and are tempted to address this uncertainty through the use of energy consuming air conditioning systems. This approach fails to address the root cause of the problem and commits us to an endless cycle of providing more carbon intensive methods to keep us cool in an environment that has in part been warmed through manmade carbon emissions.

Provided with a green field site, most buildings in the Irish climate can be designed to produce a comfortable internal environment without the need for energy intensive air conditioning systems, even when potential temperature rises predicted for the building’s lifetime are considered.

All rooms within the Nurses Education Building, with the exception of the two lecture theatres and the toilets, are naturally ventilated, and these remaining areas are treated with a carefully controlled ventilation system that contains no mechanical cooling.

If a building’s structure and fabric are to provide its air conditioning system the starting point must be the building’s form which has to address natural ventilation, thermal mass, energy storage, daylight, and control of solar gain in warmer months.

The building has a clear north/south orientation which allows the solar gain to be addressed in the summer months through both the use of the step in the building’s façade and the solar shading provided.

In addition to the reduction of solar gains, internal lighting gains are minimised through the use of a fully dimming lighting control system which pulls down the artificial lighting levels to compensate for natural daylight.

There are two natural ventilation strategies at work, as illustration 1 shows. On the micro scale, high and low level openings on the south façade, coupled with shallow plan rooms offer quality single sided ventilation. The upper windows are motorized to allow the high level openings to double up as part of the night cooling solution.

There are however a number of rooms which by their function require larger room depths and a cross ventilation strategy is applied, using the huge stack driving force of the central atrium to drive fresh air through the rooms.

Rooms on the north façade that have narrower room depths and are exposed to lower heat gains are provided with single sided ventilation which can be provided at a lower cost than the strategy used in the larger rooms.

Thermal mass has been maximised through the use of exposed soffits (ceilings) throughout the building in addition to exposed beams and columns. This mass is cooled during the night by use of the motorized windows on the south façade in conjunction with the large atrium smoke vents which double up as a natural cooling system. Air is drawn through the deeper rooms by small, acoustically attenuated air vents at the rear of the rooms.

Costs are carefully minimised through motorizing the south facing high level windows, while allowing the north facing windows in the smaller, cooler office spaces to remain manually operated.

Distribution

As an educational building, it is filled with a large number of services, including an extensive information technology network, and specialist compressed air and vacuum services that simulate a medical gas installation.

The routing of these services around a building that is entirely fitted with exposed soffits and no raised floors, while concealing all of the services distribution requires very careful co-ordination by the design team and contractors before work begins on site. The exposing of beams and columns makes this task even more critical as the main service routes travel straight through beams and columns which can not be drilled after completion and must be fitted with sleeves in exactly the right locations as the building structure is cast.

There are highly formalized service distribution routes within the atria, from which services travel through room perimeter beams to reach services such as light fittings. Sleeves for light fitting services must be cast into beams as the building structure is poured with precision. There is no room for second chances.

In one case it was necessary to cast in a sleeve for a drainage pipe between two floors, at an angle through beam and column body to weave through to the required service drop without exposing it at either floor.

In a traditional building construction, many of the finer details of services routing are left until the services are being installed as it is easier to visualise and resolve problems as they occur, but a cast concrete building leaves no tolerance for this approach and all difficulties must be resolved before the structure is cast.

Concealed pipework from the radiators travels through the column at the far end of the image (bottom left). Sleeves were cast into the column at the precise height required to line up with radiator connections while the building structure was under construction and long before any pipes were fixed to allow measurements to be taken. This level of co-ordination requires a much higher degree of early thorough detailing than a traditional layout. In the case of the radiator pipework, a sample radiator and connections were prepared and agreed to allow precise dimensions to be determined before the actual construction took place.

The success of this extreme co-ordination that eliminated every last exposed pipe from the building was made possible by the close interaction between the Waterford Institute of Technology client, A&D Wejchert architects, BDP services engineers, and the construction team of Cleary Doyle.

Computer room

Computer rooms contain large internal heat gains and are not traditionally handled with natural ventilation. The challenge presented by the computer room in this building is further increased by its location on the south façade, and the use of a large area of glazing, but the design team were determined to meet the challenge through natural means.

In addition to the building step and solar shading used to reduce solar gains reaching the glazing, specialist glazing has been used.

Okasolar was specified, a product consisting of a double glazed panel fitted with a series of mini light shelves which are solar selective - they passively decide how to handle sun light depending on its angle of incidence.

Okasolar has significant advantages over the use of blinds as it allows natural light into the computer room without causing glare in addition to reducing solar heat gain.

Computer rooms are not traditionally suited to natural lighting but in this case the selective glazing allows quality daylight to be achieved without producing significant screen glare.

The natural ventilation is boosted through the provision of openings on three sides of the room, ensuring a pressure difference between openings is always available. The motorized vents and exposed mass also work together to maximise the space’s night cooling potential. The strategy has produced a comfortable teaching environment and shows that even high gain spaces with large areas of glazing can be provided with successful natural ventilation strategies.

Heating

It can be difficult to achieve a passive solar design in a large building as the quantity of accommodation results in a double loaded circulation arrangement. Significant advantage can however still be made of passive solar design through the careful location of spaces within the building. In this building, the deeper teaching spaces are located on the south façade and the shallow office spaces are placed on the north façade. This means that a larger area of rooms face south than north and are therefore able to take advantage of useful passive solar gain during cooler weather.

The use of selective solar control in the form of horizontal shading and the step in the building’s façade removes high angle summer sun while still allowing useful winter solar gains to enter the building. This selective control can-not be achieved through the use of horizontal shading or solar control glazing which permanently block solar gain.

The building was designed to have an air tightness of 5m3/m2/hr at a test pressure of 50Pa and its success was proved through a building air test carried out by Building Envelope Technologies. The initial air test came close to the target figure and a smoke test revealed a number of key leakage points such as services entries into the plant room, and the roof smoke vents.

Thanks to the builder’s persistence and a large volume of mastic, the test result was achieved following remedial measures.

The building’s wall structure consists of brick – cavity – block – services cavity – and internal dry lining, and the roof is a light-weight roof. There were no particular air seal tapes or other expensive specialist air sealing materials used during the building’s construction and the result demonstrates that a good air tightness level can be achieved through the application of good workmanship and attention to detail.

The building’s insulation properties were only slightly greater than the building regulations requirements, with low emissive glazing used to improve the glazing properties, however with air leakage responsible for half a building’s heat loss, the air tightness achieved was a significant and cost effective improvement to the buildings thermal performance.

Heat is provided by two fully condensing, fully modulating gas boilers. The boilers are fitted with a direct weather compensation control routine to ensure that they remain in condensing mode almost continuously. The boilers are very small relative to the size of the building and raised a number of cautious comments from the building’s maintenance crew during construction. Luckily the confidence placed in the design was proved during the building’s testing period.

In addition to the main boiler compensation, further trimming is provided by a north and south compensated circuit, with final temperature control handled by individual room temperature controls.

Under floor heating is used within the main atrium space in order to keep the heat provided close to floor level and avoid over stratification. All pumps are fitted with variable speed drives that automatically reduce their volume flow as the heating load reduces, by sensing the increasing pressure across the pump head as the various building valves shut down.

Natural light

Excellent levels of natural light are provided throughout the building. Daylight levels above 5% average daylight factor are produced in most rooms meaning that the artificial lighting can be left off for 80% of the occupied period. In addition to the external glazing, the central atrium is flooded with natural light and this light is diffused through transfer glazing to the back of spaces either side of the atrium. The internal glazing also helps to create a transparency between the lecture and office spaces.

All pumps are fitted with variable speed drives that automatically reduce their volume flow as the heating load reduces, by sensing the increasing pressure across the pump head as the various building valves shut down

Lecture theatres do not traditionally allow natural light due to the need for projection but the design team were committed to introducing an element of natural, reflected light. The design team have integrated a roof light to the rear of the lecture theatres to draw an element of reflected light from the internal atrium.

The front of the lecture theatres are also fitted with concealed side windows to provide natural light but also to provide the lecturer with a contact with the external environment.

Mechanical ventilation

While the toilet extract ventilation system must run continuously during occupation, it is coupled with a thermal wheel heat recovery system that recovers most of the waste heat from the exhaust air. This system is also linked to the building’s main communications room and is therefore capable of recovering an element of heat from the I.T. equipment within that room. While a mechanical ventilation system is used within the lecture theatre, its controls are carefully programmed with an advanced control routine that minimises energy usage.

Most modern lecture theatres are fitted with displacement ventilation systems that introduce air below seating. This strategy minimises the amount of cooling required by delivering cool air directly where it is needed, rather than mechanically cooling it to several degrees below the room temperature as required for a high level ventilation system. When a displacement system is used in the Irish climate there is no need to provide further, energy consuming mechanical cooling.

A lecture theatre is traditionally controlled with a time schedule, the intention being that the lecture times will be programmed in, with the system only running when a lecture is in progress. Building managers are however too busy to continuously program in lecture times and the systems are usually left on from the start of the day until the end, run at full volume on the assumption that the lecture theatre is fully occupied even though it is often only partly occupied or completely empty. In the Nurses Education Building, the lecture theatres are fitted with Carbon dioxide, temperature and PIR sensors which can detect if the room is in use and give an indication of how many occupants are in the room. The system automatically shuts down if the room is not in use and when occupied, automatically reduces the volume of air supplied to the minimum required to provide fresh air for the space. The air handling unit is also fitted with a thermal wheel to recover waste heat from exhaust air. The thermal wheel speed is controlled by a variable speed drive and can adjust its speed automatically to adapt the level of cooling provided by the air handling unit.

The lecture theatres are fitted with displacement ventilation systems that introduce air below seating, minimising the amount of cooling required by delivering cool air directly where it is needed

Typically, a lecture space is vacated between lectures and the system will automatically detect the break and shut down. Air can however still be drawn naturally through the space via an acoustically attenuated transfer vent to the atrium.

This natural vent allows the room to be filled with fresh air through natural means between lectures and also allows an element of night cooling to take place naturally during warm weather as the atrium vents open, part of the night cooling strategy.

Building controls

While the building contains relatively few climate control systems, they are managed by a computerised building management system, containing a web server and linked through the college’s local I.T. system, allowing the building’s controls to be accessed, and modified from any computer in the campus by the WIT maintenance staff. WIT has recently moved to a web based control system to allow them to easily manage all of their buildings over their large campus from any point connected to their I.T. system. BDP have also set up a link from their own offices to the Nurses Education Building and can check in on the building under various weather conditions, allowing them to identify minor adjustments to the control system that will increase the buildings energy efficiency.

Overall the Nurse’s Education Building demonstrates that it is possible to produce a low energy building without any additional expenditure that does not compromise on user comfort, visual image, or build quality, through careful design, co-ordination, and teamwork.

Project team members:

Client: Waterford Institute of Technology

Architect & design team leader: A&D Wejchert and Partners

M&E and environmental engineers: Building Design Partnership

Structural engineers: O’Connor, Sutton Cronin

Quantity Surveyors: Bruce Shaw Partnership

Main Contractor: Cleary Doyle

- Articles

- Climate Change

- Intensive Care

- Nurses Education Building

- Waterford

- exposed soffits

- passive solar design

Related items

-

Property industry faces ‘triple threat’ from climate crisis

Property industry faces ‘triple threat’ from climate crisis -

Irish Green Building Council launch event to promote sustainable building practices

Irish Green Building Council launch event to promote sustainable building practices -

Ashden Awards winners showcase climate solutions

Ashden Awards winners showcase climate solutions -

‘Sufficiency’ key alongside energy efficiency & renewables, says IPCC

‘Sufficiency’ key alongside energy efficiency & renewables, says IPCC -

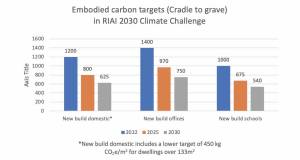

RIAI launches 2030 climate challenge

RIAI launches 2030 climate challenge -

Climate action plan sets embodied carbon targets for construction

Climate action plan sets embodied carbon targets for construction -

Grant invests in biofuel tech for oil boilers

Grant invests in biofuel tech for oil boilers -

Architects call for urgent climate action ahead of COP 26

Architects call for urgent climate action ahead of COP 26 -

The PH+ guide to overheating

The PH+ guide to overheating -

Net zero carbon plans back renewables over fabric

Net zero carbon plans back renewables over fabric -

Building sector must show bold climate leadership

Building sector must show bold climate leadership -

Deep retrofit crucial to green recovery, climate committee says

Deep retrofit crucial to green recovery, climate committee says