- New build

- Posted

Ireland's first passive house pharmacy

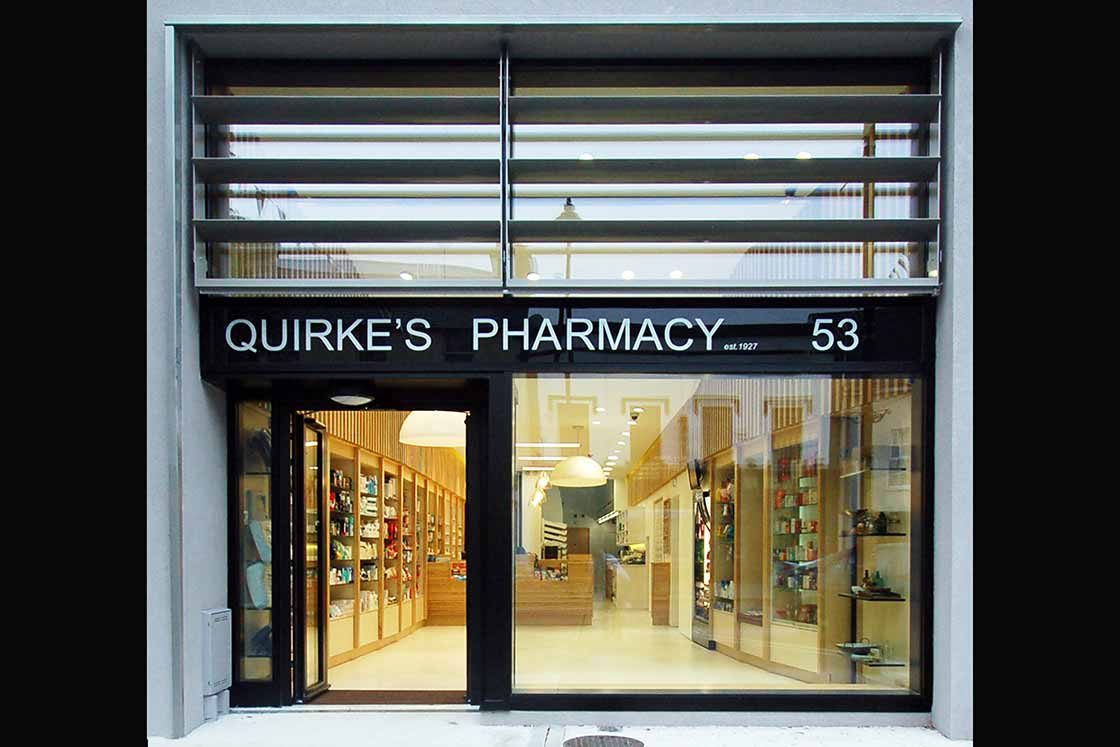

Late last summer, work finished on architect Paul McNally’s latest super low energy project: a three-storey building in Tipperary that has just become Ireland’s first certified passive house pharmacy.

Since 1927, the Quirke family has been running a pharmacy on the main street in Clonmel, Co Tipperary. The original building on their O’Connell Street site was over 200 years old, but in poor shape.

“It was in a bad, bad state of repair,” says current proprietor Ronan Quirke. “It was always my intention to do something with it.”

For a start, the dispensary was too cramped for his staff. “The old space that they were asked to work in for many years was appalling,” he says. The shop also suffered from a low ceiling height, poor layout and lack of insulation.

Upstairs in the three-storey terraced building was a residence that hadn’t been occupied for at least 40 years, which was just being used for storage.

Quirke approached architect Paul McNally of The Passivhaus Architecture Company, who had previously designed a low energy extension to Quirke’s Georgian home on Anne Street in the town.

They looked at the possibility of retrofitting, but there were so many structural issues that retaining the old building would have required serious interventions, and would have been expensive.

“To make the upper floors usable to modern standards would have taken a huge amount of work,” McNally says. Meanwhile the shop was “a mess spatially. It was a nightmare really to work in, and it was freezing.”

Quirke decided to knock the old building, which wasn’t a protected structure, and rebuild from scratch. But he was insistent that whatever building replaced it last a lifetime — he didn’t ever want to have to renovate again. “I only wanted to do this once. I certainly didn’t in 20 years want to be faced with a further patch job,” he says.

“I wanted to future proof it,” he says. Construction costs had bottomed out at the time too, which meant he could get more bang for his buck. Quirke asked McNally what the highest standard he could build it to was, and McNally told him about passive house.

But Quirke says: “It also had to be cost-effective. I wasn’t going to keep throwing money at the project just to achieve certification for certification’s sake.”

McNally adds: “He was pretty keen to achieve the standard, though it wasn’t an absolute requirement.”

Local contractor O’Gorman Construction, who had built Quirke’s home extension at Anne Street, was appointed here. Being in a terrace, knocking and rebuilding posed obvious structural challenges. An archaeologist was also on site at this stage of the job.

“During the planning and research, we found out that the ruins of Ireland's second quaker meeting house formed the walls of our site boundary, so we had an archaeologist on site during all the excavation and demolition works,” McNally says.

This article was originally published in issue 10 of Passive House Plus magazine. Want immediate access to all back issues and exclusive extra content? Click here to subscribe for as little as €15, or click here to receive the next issue free of charge

O’Gorman Construction knocked out the ground floor of the old building, before constructing a steel frame that would support both the neighbouring buildings and the rebuilt pharmacy. Once the steel frame was up, the upper floors of the old building were demolished.

“We had a very good contractor,” McNally says. “He was a great contractor we had complete faith in, he had local knowledge of the buildings on the main street in Clonmel.”

The steel frame was installed on Foamglas Perinsul blocks to avoid thermal bridging between it and the concrete slab. After demolition, work began on the new building. The team looked at various options for constructing the new pharmacy, but concrete block with an insulated, ultra wide cavity proved the most cost-effective.

The principle walls of the new building feature two leafs of 100mm blockwork, with a 250mm cavity insulated with bonded polystyrene bead, and Gyproc Airtite plaster internally. Cavities were also created by constructing single leaf blockwork walls 250mm from the party walls, and again insulating with bonded bead. In all cases, Ancon Teplo thermal bridge free walls ties were used to bridge the cavities

The ground floor features 150mm of Xtratherm PIR insulation board under the slab, while the timber roof is insulated with mineral wool between the rafters and in the service cavity, plus an extra layer of Gutex Ultratherm woodfibre board. Munster Joinery Alu-P Passive House Institute certified windows were specified, while the front of the shop features a glazed Batimet passive house certified triple-glazed curtain walling system, supplied and installed by PJ Bowes.

The pharmacy faces south onto O’Connell Street, but the buildings on the far side of the road overshadow the ground floor facade, blocking solar gain.

“The solution was to raise the shop floor ceiling height to a storey and a half and install full height glazing, so that even on the winter solstice, solar gain penetrates the store,” McNally says.

Being in a terrace there was little scope for glazing on the east and west gable walls, so roof windows were installed in the single storey projection to the back to bring in more natural light.

Perhaps not surprisingly on such a complex project, the biggest challenge was airtightness. During the installation of precast concrete slabs at second floor level, connecting airtightness membranes were ruptured. Because the concrete hollow core slab-edge was compromised, penetrations (such as for services and stair opes) within the floor had to be sealed individually, whereas had the membrane been protected at the edge, this may not have been necessary. Extensive remedial work was required to get down to the passive house airtightness standard.

But McNally praises his contractor’s persistence to get the result down to the passive house requirement of 0.6 air changes per hour. “He was never going to give up.”

Contractor Barry O’Gorman says this was the most energy efficient and airtight building he has ever worked on. While he had experience of building down to around one air change per hour before, 0.6 was a different kettle of fish.

“It was a whole new challenge,” he says, adding that in practice the difference between these two figures — which seem so close together — is “massive, it’s unbelievable”.

Even if the team hadn’t been aiming for passive house, the nature of the site would have still made it a rather unique job. “Every day was a challenge in there,” O’Gorman said. “I don’t think you’d come across anything as complicated again.”

-

Before renovation

Before renovation

Before renovation

Before renovation

-

Munster Joinery Alu-P window cill detail

Munster Joinery Alu-P window cill detail

Munster Joinery Alu-P window cill detail

Munster Joinery Alu-P window cill detail

-

The ground floor features 150mm of Xtratherm PIR insulation board under the slab

The ground floor features 150mm of Xtratherm PIR insulation board under the slab

The ground floor features 150mm of Xtratherm PIR insulation board under the slab

The ground floor features 150mm of Xtratherm PIR insulation board under the slab

-

Fakro roof windows were installed to bring in more natural light

Fakro roof windows were installed to bring in more natural light

Fakro roof windows were installed to bring in more natural light

Fakro roof windows were installed to bring in more natural light

-

Windows installed on spacers

Windows installed on spacers

Windows installed on spacers

Windows installed on spacers

-

Foamglas Perinsul structural insulation on a pile cap

Foamglas Perinsul structural insulation on a pile cap

Foamglas Perinsul structural insulation on a pile cap

Foamglas Perinsul structural insulation on a pile cap

-

Gaps filled with insulation

Gaps filled with insulation

Gaps filled with insulation

Gaps filled with insulation

-

A look inside the extra wide 250mm wall cavities prior to insulation

A look inside the extra wide 250mm wall cavities prior to insulation

A look inside the extra wide 250mm wall cavities prior to insulation

A look inside the extra wide 250mm wall cavities prior to insulation

-

Insulated cavity closers provide an efficient solution to closing the cavity at window and door reveals

Insulated cavity closers provide an efficient solution to closing the cavity at window and door reveals

Insulated cavity closers provide an efficient solution to closing the cavity at window and door reveals

Insulated cavity closers provide an efficient solution to closing the cavity at window and door reveals

-

The rear of the pharmacy

The rear of the pharmacy

The rear of the pharmacy

The rear of the pharmacy

https://passivehouseplus.ie/magazine/new-build/ireland-s-first-passive-house-pharmacy#sigProIdc581a6dfb6

Building a shop posed other issues too. The team were already on site when McNally realised the lighting design wasn’t going to offer sufficient illumination in the shop area. “Lighting for retail is quite a specific skill,” he says.

He brought in lighting experts Domus Projects to advise. “They came up with a scheme that allowed us to get very high levels of illumination with very low levels of energy.”

Quirke was also keen to have automatically opening doors for the pharmacy, so that customers in wheelchairs — or with buggies — could get in easily. Custom-made triple-glazed automatic doors from Irish Door Systems were specified.

But in a busy shop where the doors are opening constantly, the heat loss here could have threatened the team’s passive house ambitions.

Working with passive house consultants MosArt, the door losses were quantified and modelled. While increasing insulation might have offset the annual load, it wouldn’t have addressed instantaneous heat losses.

So to be safe, McNally specified a hot air blower inside the shop above the door. The unit draws on heat supplied by the shop’s gas boiler, and warms cool air that enters through the doors. This system has not been called into action during the first heating season, but will cover future extreme events.

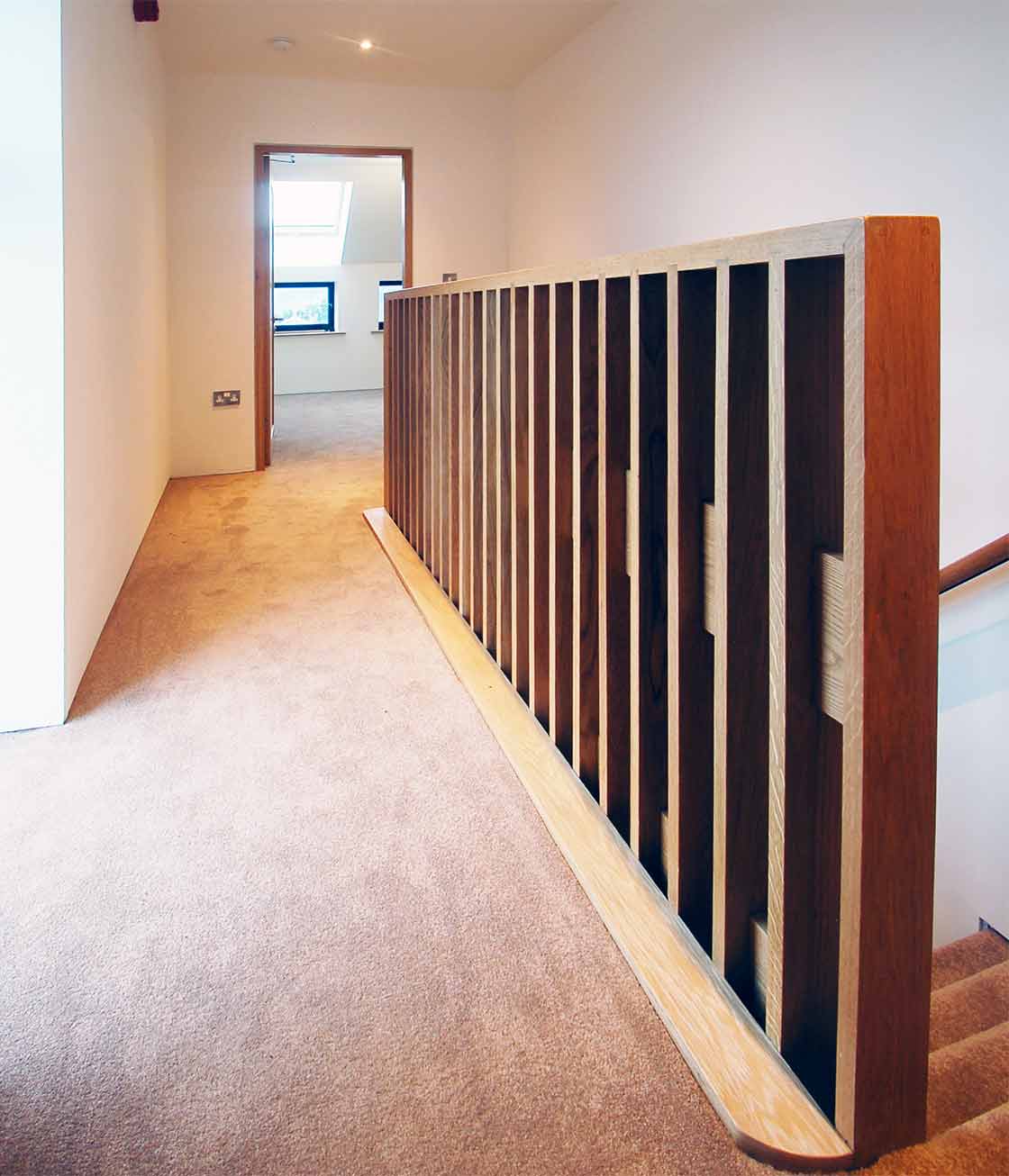

The small thermostatically controlled condensing gas boiler also delivers heat to a single radiator in the shop. Quirke opted to put a new two-storey apartment in the space above the pharmacy, and though it isn’t occupied yet, it’s heated by a Nilan Compact combined heat recovery ventilation and air-to-air heat pump system, which also provides domestic hot water. Hot water produced by Kingspan Thermomax solar thermal collectors is integrated into the system.

Meanwhile the pharmacy is ventilated by a Paul Novus 300 MVHR system. The automatic doors were kept open until November last year too, throwing some natural ventilation into the mix too.

The project came in on budget, and the pharmacy opened a month ahead of schedule. McNally is now undertaking post occupancy analysis, with data loggers measuring temperature and humidity inside. Up until Christmas, temperatures in the pharmacy were around 20 to 21C, with no heating on at all. He says the additional heat gains from retail lighting, computers, CCTV and other electrical equipment in the pharmacy are providing the majority of heat load. January and February saw Quirke using one hour of radiator heat each morning. Passive house certification has just been achieved. McNally says the only theoretical stumbling block was the relatively higher primary energy demand of the pharmacy, but the lower demand of the apartment and concessions for retail energy use made it possible.

The only teething issues to date have been with the triple-glazed electronic doors. “There were tweaking issues. But if that was the only major problem we had, then we haven’t really had a problem to be honest with you,” Quirke says.

The building is warm, comfortable, spacious, energy efficient, properly ventilated — everything you would expect from a passive house. As Quirke says: “It would have been futile to do this exercise and not get those things.”

He observes that, for the tradesmen turning up on site during the build — carpenters, electricians, block layers and so on — the project was almost like a training course. “Every tradesman who turned up wanted to learn something about passive house,” he says. “Everyone was doing something they hadn’t done before.”

“I just think it’s a really great thing, that everybody has got something out of this,” he says.“I’ve got a great building�and the builders got something out of it, and all the subcontractors down the line got something out of it.”

Selected project details

Client: Ronan Quirke

Architect: The PassivHaus Architecture Company

Main contractor: O’Gorman Construction

M&E engineer: Overy & Associates

Civil & structural engineer:Tanner Structural Designs

Quantity surveyors: Duffy Quigley

Mechanical contractor: Tierney Mechanical Services

Electrical contractor: Clantech

Airtightness tester: 2eva.ie

Bonded bead insulation: Dungarvan Insulation

Wall ties: Ancon

Thermal breaks: Foamglas

Mineral wool insulation: Isover

Airtightness products & wood fibre board: Ecological Building Systems

Floor insulation: Xtratherm (now Unilin)

Airtightness products: Ecological Building Systems

Windows & doors: Munster Joinery

Roof windows: Fakro

Curtain walling: PJ Bowes

Brise soleil: QEF

Automatic entrance doors: Irish Door Systems

Green cement: Ecocem

Integrated heat pump/MVHR system: Nilan Ireland

Gas boiler: RVR

MVHR: Ollie McPhillips Building Energy Services

Pharmacy Lighting: Domus Projects

Cavity closers: SIG Insulation

Renders: K-Rend

Project overview

Building type: Treated floor area Pharmacy 111 sqm, Treated floor area Apartment 117 sqm, Duplex apartment over Pharmacy. Mid-terrace building of masonry wall with steel frame construction.

Location: O’Connell Street, Clonmel, Co Tipperary

Completion date: August 2014

Passive house certification: certified

Energy targets (respectively for pharmacy & apartment)

Space heating demand (PHPP): 12/15 kWh/m2/yr

Heat load (PHPP): 11/11/W/m2

Primary energy demand (PHPP): 163/89 kWh/m2yr

Airtightness: 0.6/0.6 ACH at 50 Pa

Energy performance coefficient (EPC): 0.41/0.29

Carbon performance coefficient (CPC):0.42/0.31

BER:A3 (380.86 kWh/m2/yr) /A2 (46.75 kWh/m2/yr)

Thermal bridging: first course of Quinn Lite blocks, low thermal conductivity cavity wall ties, thermally broken window frames, insulated reveals, FoamGlass beneath steel structure, SIG proprietary cavity closers, Vertical Quinn Lite course at curtain wall jamb. Y-value (based on ACDs and numerical simulations): 0.08 W/mK

Ground floor: 150mm Xtratherm insulation under floor slab. U-value: 0.14

Walls: K-Rend render on 100mm blockwork. 250mm graphite enhanced EPS bonded bead, concrete block 100mm, Airtite plaster. U-value: 0.124

Roof: Tegral Rivendale slate, tiling batten on 40mm counter battens, Solitex Plus membrane, with all joints taped and sealed with Proclima Tescon Vana tape, 30mm Gutex Ultratherm wood fibre insulation on marine plywood 125mm timber cross members on 225mm rafters, full fill 350mm non combustible Isover Ireland Metac mineral wool insulation. Intello plus membrane vapour control layer, 100mm service void of 2 layers of 50mm each batten and cross batten FSC softwood filled with full fill Metac 100mm mineral wool insulation. U-value: 0.097

Windows: Munster Joinery Alu-P passive house certified aluminium window. Overall U-value: 0.8 Batimet TM50 SE Passive House Institute certified Curtain walling. Ucw installed 0.85

Heating system

Pharmacy: Victrix X 12kW condensing gas boiler, heating one radiator and one air curtain.

Apartment: Thermomax tube solar hot water panel preheating Nilan compact P unit, which provides heating, DHW and heat recovery ventilation.

Ventilation

Pharmacy: Paul Novus 300 F 84% efficiency Passive House Institute certified.

Apartment: Nilan compact P unit, as described above.

Green materials: all timber fittings from FSC certified sources, 50% GGBS cement