- Case Studies

- Posted

Coillte Teoranta

Coillte Teoranta (The Irish Forestry Board) headquarters is a state-of-the-art premises located in Newtownmountkennedy, County Wicklow. The building is the first all timber office complex in Ireland. It covers almost 2,300m2 of floor space and provides accommodation for almost 100 staff working in a wide range of forestry related disciplines.

The building, designed by the environmentally aware architect, Duncan Stewart of Stewart Sinnot Studio, was built in two phases. The first phase, which was completed in 1997 has been home to Coillte’s Southern Region. The second phase, which was factory pre-fabricated by Griffner Coillte in Mullingar, is only just complete and merges to form the new Corporate Headquarters. Buro Happold was involved in the second phase of this project, which was the 1000m² extension to Coillte’s original premises. The challenge was not only to build an extension to the existing Coillte office building, but to add several 'green' touches to both buildings, which will make the new office unique in Ireland. The aim was to create a corporate headquarters that demonstrates not just best practice in timber building tecgrahnology but also best practice in all-round sustainable design. Coillte intends for the building to act as a beacon for building developers and design professionals, showing them what is possible in terms of sustainable design and helping them understand the issues associated with the installation of these features.

While the existing building was ahead of its time in terms of demonstrating best practice in timber building technology, the new one seeks to build on this experience and to demonstrate best practice in all around sustainable design with the primary building material being timber from sustainable sources and insulation using recycled paper product to levels better than current Building Regulations standards.

The building is designed with a narrow plan to encourage natural cross ventilation via opening windows. The windows are designed to have different opening positions to provide trickle / background ventilation in Winter, minimal ventilation in Spring and Autumn and large full opening areas for Summer ventilation. High level windows are motorised and can provide secure night time cooling in Summer as required. A generous brise soleil (overhang) has been provided at roof level to minimise high angle summer solar gains whilst allowing the gains from low angle sun to help heat the building in Winter. High level windows in the sloping roof also have inbuilt retractable external blinds to reduce solar gains in Summer but without daylight or heat penalty in Winter. The demand for mechanical cooling is therefore removed and in addition the high insulation levels ensure very low heat demands in Winter.

A high quality of prefabrication workmanship ensured the minimum of waste, coupled with a very high accuracy and quality of finish. A high speed of manufacture was ensured by Griffner Coillte, optimizing the whole production process. The prefabrication of complete modular walls ensured the accuracy of assembly, and the manufacture of finishes took place in factory conditions. As much as possible was made offsite, limiting the associated unpredictability. The adoption of energy efficient construction effectively guarantees the building’s contribution towards a reduction in CO2 emissions as required under the Kyoto Protocol. The product complies fully with Irish Building Regulations and in addition is undergoing independent Certification with TRADA Technology. The building materials used are free of all volatile organic compounds, with the pressed wood boarding used being formaldehyde and urea-formaldehyde free. The paints which were used are phenol free and the insulation was treated with jute and boron salt to protect against mould and insects whilst also improving the fire rating.

Coillte is especially conscious of its commitments under the Kyoto Protocol to reduce CO2 emissions and believes that Ireland has a strong but as yet undeveloped potential for biomass energy production. With the large proportion of Irish forests that Coillte manage, they are in an excellent position to utilize this potential and start an Irish timber biomass industry through the harvesting of wood residue from saw mills and forestry (Editor’s note- there are already companies set to begin production of pellets from saw mills and forestry early this year).

In light of this, it makes sense that the new building contains a large-scale commercial installation of a wood pellet/wood chip fuelled boiler, used as the second stage heat generator for the building. The boiler installed was a KWB USV 100, which has an output capacity of 95kW and has an efficiency of 85.6% at rated output and 85.4% on part load. Coillte are hoping to demonstrate the wood chip capabilities but will be mainly running from a 20m2 adjacent pellet store via an automatic feed system including an agitator within the store and an automatic feed conveyor system. The boiler will deliver approximately 152000kWhrs of renewable heat a year, reducing CO2 by 27,360kg compared with natural gas.Two arrays of solar thermal panels, which are made up of a flat plate array and an evacuated heat tube array, are the primary heat source. A large buffer vessel is used to store this heat, which is topped up from the wood chip boiler when necessary. Both of these systems are located in a purpose built Energy Centre, which also contains full monitoring and feedback facilities. The Energy Centre generates heat entirely from renewable sources and is carbon neutral in terms of CO2 emissions. The building is fully sustainable with the primary building material being timber from sustainable sources, insulation by recycled paper product to levels better than current building regulations, passive solar design incorporating brise soleil, external fixed and retractable solar shading and very high quality glazing.

The building is open to the public for education and demonstration purposes and a meeting room has also been designed with full audiovisual facilities for lectures and discussion purposes.

Gerry Cunnane of Wind, Water, Solar Energy Systems describes the Thermomax Solar installation at the Coillte offices.

" The solar installation in the Energy Centre at the Coillte Headquarters consists of two separate Thermomax solar panels, one evacuated tube type and one flat plate, linked in parallel to a 1,500lt insulated buffer tank. Both solar collectors have the same effective area (9 square meters) and are fitted with data loggers capable of recording the respective outputs over time. In this way it will be possible to compare the performance of each collector type in Irish conditions. This information will add to the body of knowledge being built up regarding the performance of solar thermal in Ireland."

- forestry

- timber frame

- Duncan Stewart

- thermomax

- biomass

- Ventilation

- kyoto treaty

- greenhouse emissions

- coillte

- teoranta

Related items

-

Peaky blinder

Peaky blinder -

Why airtightness, moisture and ventilation matter for passive house

Why airtightness, moisture and ventilation matter for passive house -

Up to 11

Up to 11 -

It's a lovely house to live in now

It's a lovely house to live in now -

We Build Eco flat pack timber frame partnership gathers pace

We Build Eco flat pack timber frame partnership gathers pace -

ProAir pioneers with EPDs for ventilation systems

ProAir pioneers with EPDs for ventilation systems -

Mass timber masterwork

Mass timber masterwork -

AECB conference to showcase timber innovation

AECB conference to showcase timber innovation -

Let’s bring ventilation in from the cold

Let’s bring ventilation in from the cold -

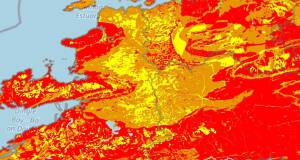

45,000 more Irish homes face radon risk, new maps reveal

45,000 more Irish homes face radon risk, new maps reveal -

Heart of oak

Heart of oak -

ProAir retooling for the future

ProAir retooling for the future