- Marketplace

- Posted

Offsite and modular: The future of construction

New Cork school built and finished in 4 weeks

This article was originally published in issue 35 of Passive House Plus magazine. Want immediate access to all back issues and exclusive extra content? Click here to subscribe for as little as €10, or click here to receive the next issue free of charge

Offsite, modular building using sustainable materials is increasingly seen across Europe as a solution to construction delivery challenges, because it can deliver high quality buildings to extremely fast turnaround times. That’s according to Roscommon-based offsite craft building specialist Lidan Designs.

Lidan recently completed a modular building with two classrooms and an office for St Patrick’s College in Gardiner’s Hill, Cork City. The A rated NZEB building took just three weeks to build in the Lidan factory, and another week to erect and install on the difficult-to-access site.

The classroom building was finished with traditional render, with a zinc roof, aluminium doors and windows. In line with their sustainable ethos Lidan also built a wooden ramp clad in cedar. “The building has been very well received by the school and their board of management, teachers and pupils. The school consultants Matt O’Mahony & Associates in Cork said it has far exceeded all their expectations,” Dan O’Brien of Lidan Designs told Passive House Plus.

O’Brien believes this type of building represents the future of school construction as it allows schools to order modular but bespoke buildings with extremely fast delivery times compared to traditional onsite building options.

“It’s a permanent building, but it’s modularly done, completed offsite and portable,” O’Brien said. “In my opinion here in Ireland my experience is that there is too much focus on temporary or emergency solutions across the board. This is a function of continuous ineffective strategy, but possibly driven by a lack of alternative solutions, which modular is now changing. Proper forward planning with demand estimation etc. can and will alleviate the need for so-called temporary or emergency solutions.”

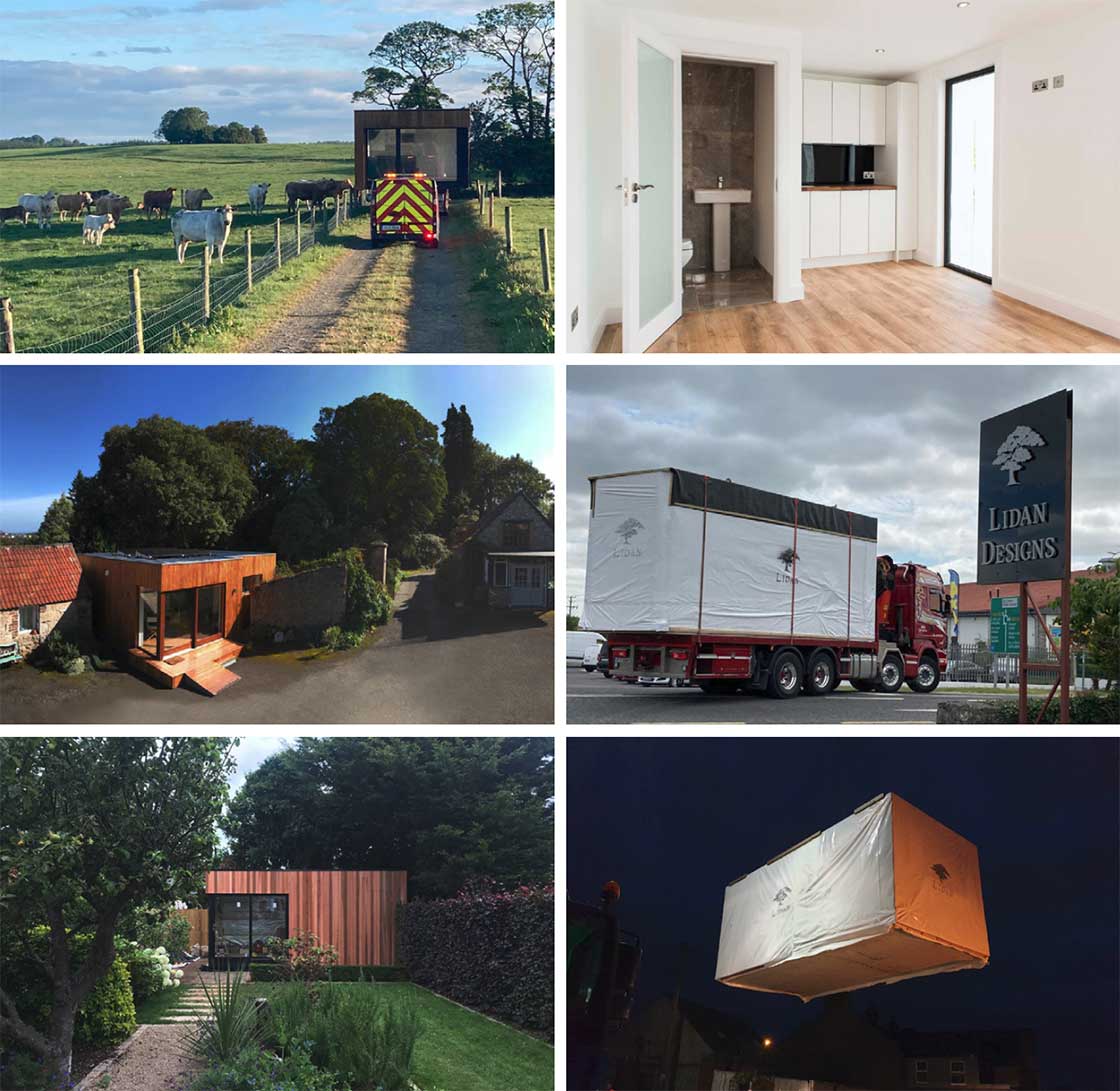

Lidan Designs specialises in small modular buildings, constructed and finished offsite;Lidan Designs specialises in small modular buildings, constructed and finished offsite;(bottom right) the house built by Lidan for Dún Laoghaire-Rathdown County Councilboasts a remarkably low carbon footprint.

O’Brien said that the Department of Education and Skills in the main have standard design and specification guidelines for school buildings, but at the same time every school wants or requires a different size. That makes school buildings ideally suited to offsite modular construction, but where there is an ability to make different size buildings. “Lidan prides itself on its flexibility in this regard and we can work from the same template but adapt it as needed in the factory,” O’Brien said.

“While there are many different definitions of modular, prefabricated and rapid build, what we have endeavoured to provide is a fully finished offsite building. This for example includes all internal plumbing and electrics up to and including the colour of paint on the walls and the external render. It’s a ‘plug and play’ offering essentially. You’re talking four weeks to deliver 1,400 square feet to NZEB standard. This includes the high levels of insulation, airtightness and designed ventilation needed to provide a warm, comfortable and healthy indoor environment for learning.”

He continued: “And because we are operating offsite, we can ensure quality at speed. Research shows across Europe that a lot of time — up to 50% is one estimate — is lost with traditional onsite construction due to the challenges of dealing with weather, sequencing, and subcontractors etc. We’re not saying all construction solutions will move to offsite, but it has a big part to play going forward.”

Lidan Designs is based in Roscommon town and makes all of its buildings in its factory using sustainably sourced timber and other natural materials.

Wet and windy

“We also know that it’s more difficult to deliver airtightness and insulation details on a wet and windy building site,” O’Brien said. “By taking it fully offsite, we can deliver guaranteed build times to NZEB standard. This makes it ideal for school building, where delivery often needs to be to very specific timetables.”

He continued: “We endeavour to use our own full-time tradespersons, rather than subcontractors, meaning we have more control over sequencing and quality. Completely finishing a building offsite is the key thing in terms of saving time. And because we are not delayed on site, we can guarantee a finished price too. What we have done is to have set per square metre pricing for buildings, which means we are reducing the risk to the end client and procurement leads.

“There is a huge move to offsite now. In the UK this has been driven by the government, a push towards modular and factory-built solutions, even to the point where the government there is now directly assisting modular providers.”

Ultra-low carbon

Lidan specialises in small modular buildings such as home offices, classrooms and garden rooms. The company also recently supplied an A2 rated NZEB dwelling for Dún Laoghaire-Rathdown County Council that Passive House Plus believes is the first dwelling in Ireland to be completely finished offsite, including fitted bathrooms, bedrooms and living spaces.

The dwelling was installed using a ground screw system, negating the need for concrete foundations, and significantly reducing delivery time.

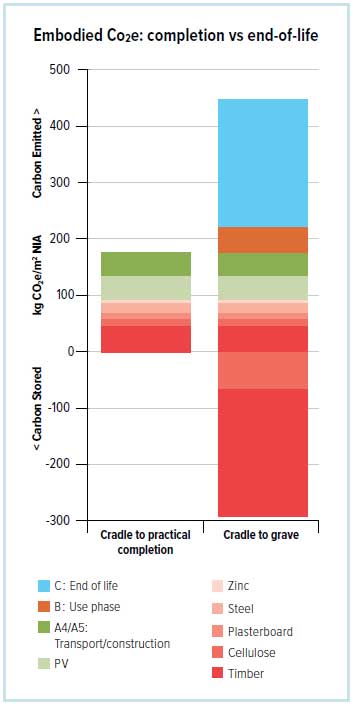

The dwelling also boasts a remarkably low embodied carbon score. According to an analysis carried out by Tim Martel, it has a full ‘cradle to grave’ embodied carbon of 157.3 kg per square metre, and a ‘cradle to factory gate’ figure of 176.4 kg per square metre.

For comparison, both figures are about half the 300 kg that the Royal Institute of British Architects (RIBA) has challenged architects to achieve under its 2030 Climate Challenge.

“This analysis demonstrates that our buildings are sustainable not just in terms of operational energy but also in terms of the embodied carbon of their production,” O’Brien said.

Lidan also recently completed executive offices for the Castle Leslie Estate and has produced a number of buildings for the Office of Public Works. The company has also recently started supplying pre-finished but bespoke home extensions, which can be delivered in rapid time.

To see a Matterport 3D tour of finished classroom buildings at St Patrick’s College, go to tinyurl.com/LidanCork. The Matterport tour was produced by 2eva.ie.

For more information see www.lidandesigns.com.

Related items

-

Build Homes Better updates Isoquick certification to tackle brick support challenge

Build Homes Better updates Isoquick certification to tackle brick support challenge -

Ecological Building Systems expands UK and Irish straw panel construction with EcoCocon deal

Ecological Building Systems expands UK and Irish straw panel construction with EcoCocon deal -

Grant’s Aerona R290: A next-gen heat pump designed for the Irish climate

Grant’s Aerona R290: A next-gen heat pump designed for the Irish climate -

Historic Dublin building retrofitted with cutting edge insulation

Historic Dublin building retrofitted with cutting edge insulation -

Proctor gains ground with Scottish passive schools

Proctor gains ground with Scottish passive schools -

Heat pump and EV charger combo promises smart energy use

Heat pump and EV charger combo promises smart energy use