- New build

- Posted

West Midlands school achieves 90 percent energy saving

Building a passive house school is a big achievement, but the team behind Oakmeadow Primary School in Wolverhampton have done something even more formidable — they built one when they weren't even asked to, and they did it for a conventional budget.

The passive house standard may have been developed for homes first, but since the early 1990s it has grown into a badge of honour for all sorts of buildings: student residences, offices, supermarkets, churches and community centres.

Schools are catching on too. As we start to think more about the type of buildings that are most conducive to learning, schools are beginning to see passive house as the ticket to a comfortable teaching environment— the antithesis of the cold, dark and dingy schools many of us grew up in, or the prefabs that dot school yards today.

Passive House Plus has already featured two pioneering passive house schools built last year in Ireland, but the UK caught on to this trend even earlier.

In 2011, leading London & Hereford-based green architects Architype designed two certified passive house primary schools – Oakmeadow and Bushbury Hill — for Wolverhampton City Council. But while many low energy schools have been experimental prototypes with big budgets to play around with, Oakmeadow and Bushbury Hill – which respectively won the non-domestic award at the UK Passivhaus Awards and the RIBA sustainability award in 2012 – were a bit different.

At first the city council had no intention of building passive house schools— until Architype said they could meet the standard for the same budget and within the same timeframe.

The council had previously contracted Architype to design St Luke's Primary School, the first in the country to achieve an 'excellent' rating under the Building Research Establishment's environmental assessment method (BREEAM).

Architect Jonathan Hines says designing passive house principles into a building from the start keeps costs down.

He says architects often spend so much of their budget on design features like complex shapes and different claddings that it doesn't leave enough money for sustainability. If you build an "elegant simple building", he says, your budget can stretch further.

"We believe you can prioritise efficiency but also create beautiful buildings," he says.

Oakmeadow's headteacher Sara Morris says Architype's enthusiasm convinced everyone to aim for the passive house standard, which she admits she knew little about before the build.

The 1960s building that housed the school before was in a bad way and its roof had suffered from vandalism. "It just was in a poor state of repair," Sara says.

Architype has a long history of building with timber — Jonathan Hines calls it a "fundamentally sustainable material"— and at Oakmeadow Irish timber frame manufacturer Cygnum supplied the frame. It was the company's first passive house project.

Cygnum says on its website that it does not source timber from forests that are converted to plantation or non-forest use, or where conservation is threatened, timber is harvested illegally or civil rights are breached. The company says its policy is to "ensure compliance" with sustainable forestry programs like FSC and PEFC.

At Oakmeadow, the timber frame walls and roof were insulated on site with Warmcel cellulose insulation, which manufacturer Excel Fibre Technology says combines "unrivalled" airtightness with breathability.

Pupils even got to bring their old newspapers in for recycling into cellulose fibres that were used to insulate the new school.

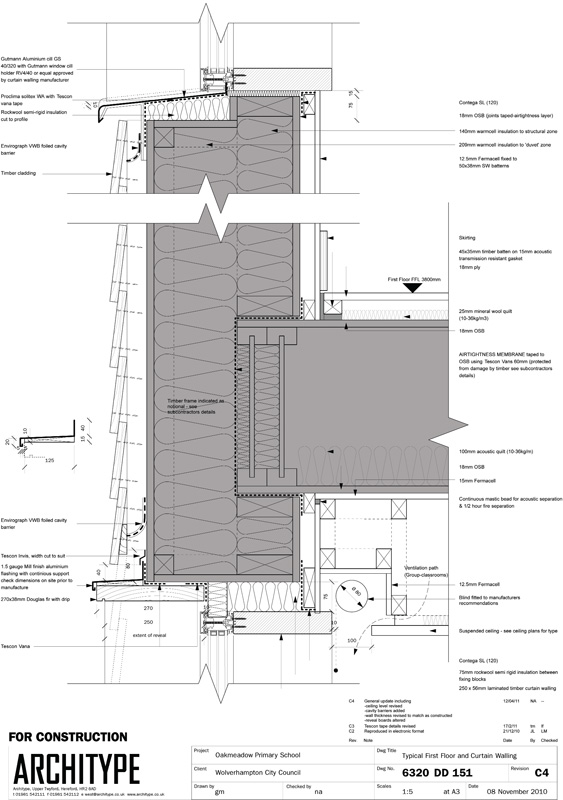

Airtightness in the walls and roof is provided by a layer of OSB boards sealed with Pro Clima tapes. Cygnum's main engineer on the project, Mark Smith, says that a "level of paranoia" was the key to achieving airtightness.

"It was a massive learning curve for us anyway. This being our first passive [project], we spent a lot of time going through the detail and design," he says.

Though based in Cork, Smith says that Cygnum is doing much of its work in the UK market, which he reckons is becoming increasingly open-minded about timber frame, passive and sustainable projects.

He commends Architype's 'fabric first' approach to reducing a building's energy demand, and says the concept of the Oakmeadow building is ultimately quite simple, though he jokes: "It didn't feel it at the time!"

The final airtightness test produced a result of 0.48 air changes per hour — safely inside the passive house standard of 0.6.

Matt Wisdom of Thomas Vale Construction, contractors on the project, says a regimented approach to airtightness ensured the target was met.

This included sending the team to Pro Clima's training facility in Germany and holding on-site airtightness workshops. The site manager's assistant also served as the project's 'airtightness champion'.

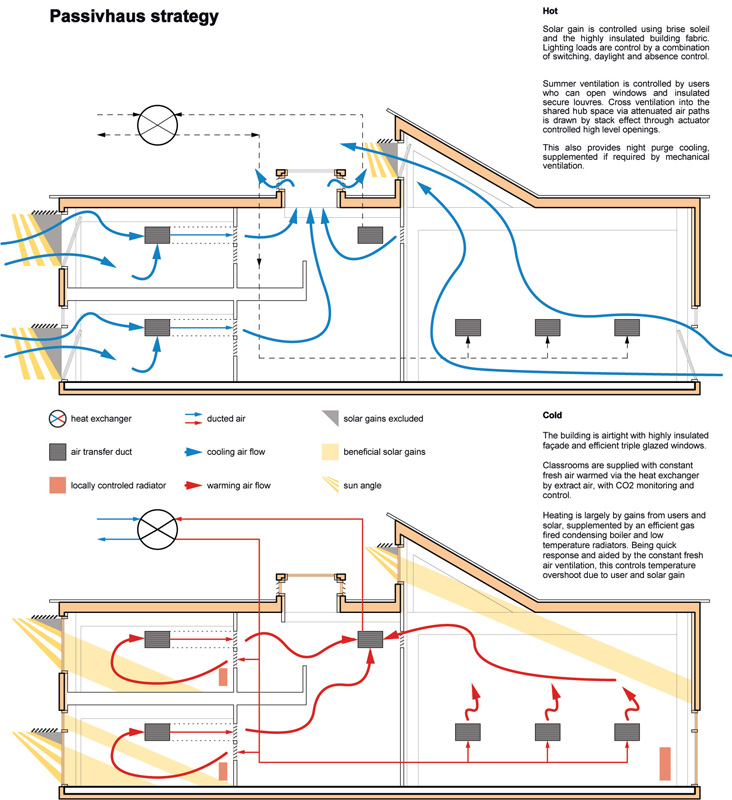

Oakmeadow boasts all the other hallmarks of a passive building too, like triple-glazing and heat recovery ventilation. There's also a 65kW Remeha gas boiler if extra heat is needed.

Jonathan Hines says he's "absolutely convinced" that mechanical ventilation is better for passive house schools than natural ventilation — because on cold winter days teachers and pupils don't open windows, meaning classrooms become stuffy and pupils get sleepy. u

No funding was available for detailed monitoring, but basic performance data suggests the building is using pretty much as much energy for space heating as the designs predicted, and the school used 90% less gas in its first year compared to the old building.

And besides its ultra-low energy consumption, Oakmeadow boasts other green badges of honour. For a start, Thomas Vale say they recycled about 95% of construction waste on site, and the building also features natural linoleum and rubber floors, plus natural paints.

The walls are also lined with Fermacell, a natural board produced with gypsum, cellulose and water — all of it recycled.

Danish-made Troldtekt ceiling tiles, made from 100% natural wood fibres mixed with cement, are used to provide sound absorption in the classrooms and sports hall.

Together with Thomas Vale Construction, the firm is using Oakmeadow and its sister school Bushbury Hill as the basis for a standardised passive house school design that can be easily rolled out on future projects. It hopes this could cut the cost of building a passive house school from £2,069 per square metre to £1,480.

Architype is now working on a new building for Wilkinson Primary School — their third passive house school for Wolverhampton City Council — and some lessons from Oakmeadow are already being applied there.

For example, the firm has designed a bespoke insulated pump house for the sprinkler system rather than use an uninsulated off-the-shelf facility like the one used at Oakmeadow.

The firm is also simplifying lighting controls at Wilkinson — which should help to reduce primary energy demand — and replacing automated windows with manual ones.

At Oakmeadow, Architype went through a detailed consultation with teachers and pupils during the design, and headteacher Sara Morris describes the new school building as "far more purposeful" than the old one.

"The new building is absolutely amazing, it's bright, it's airy," she says. "The temperatures are fairly constant."

There has naturally been a little teething trouble — Sara says mechanical heat recovery ventilation is a very new proposition for maintenance staff — but she's thrilled with the building.

"We have got a fantastic new school which the children love and they're proud of it. They're very comfortable," she says. "They don't doze off in a dingy dark classroom that's too hot."

Architect's statement:

Jonathan Hines, Architype

Over nearly 30 years of practice, Architype has developed a distinctive philosophy that inspires and guides the design of our buildings.

We creatively involve the client and users in an engagingly collaborative design process to create a building that reflects their ethos, as well as meeting their practical requirements.

We seek to be radically ecological – our focus has always been on reducing energy consumption and environmental impact by good design, rather than offsetting carbon with micro-renewables or relying on other techno-fixes or eco-clichés.

We base our design decisions on the evidence and knowledge gained from monitoring our previous buildings in order to improve the performance of future buildings.

We focus on keeping the form and detailing of our buildings elegantly simple, in order to achieve robust design and focus the budget on achieving higher quality and more sustainable buildings.

By combining all of these elements together we deliver highly sustainable buildings that are economically affordable.

Passive house offered Architype a logical progression of our approach to design. It is in effect an evidence-based quality standard that guarantees performance – maximising internal comfort and minimising energy consumption.

We had worked with Wolverhampton City Council since 2006 on a progression of projects, including the award winning St Luke’s Primary School – the first BREEAM Excellent primary school in Britain. When we proposed passive house to the council for the design of Oakmeadow Primary School, they enthusiastically endorsed it, being for them a relative small step on from the approach that they had seen succeeding in other Architype projects. However their budget was fixed to that allocated for a normal standard primary school. We faced the proviso that the approach should not affect their tight programme, their fixed standard budget, or the educational brief for the school.

The layout of the building developed from an intensive consultation with the school. Particular design challenges to achieve passive house came in a number of areas.

Form and orientation

We tested and retested ideas, looking at different orientations and options of single and two-storey. It became clear that optimising the ratio of internal floor area to external surface area was critical in minimising heat loss, and we opted for largely two storey forms orientated with all principle rooms facing north or south, to enable maximum useful solar gain with effective control of overheating and good daylighting.

Eliminating thermal bridges

The construction approach is based on previous projects (lightweight well-insulated timber frame), but went a step further. To reduce thermal bridging and achieve passive house airtightness we used a simplified load bearing stud wall (instead of structural I-beam) which is wrapped by an additional ‘duvet’ layer of insulation created by Larson trusses.

We eliminated all structural penetrations of the thermal envelope, with roof overhangs and canopies constructed outside of the thermal envelope, and any elements of loadbearing structure contained inside the thermal envelope.

The foundations were rethought completely to create a fully insulated concrete slab, floating on rigid insulation, which returns at the edges to meet the duvet layer in the wall.

Achieving the rigorous airtightness standard

We rigorously worked and reworked every detail, eliminating complex junctions and seeking the most logical, simple and buildable solutions, in order to assist the contractor, Thomas Vale Construction, in achieving passive house airtightness.

We held workshops involving key site staff and subcontractors (timber frame, windows and airtightness tape sub-contractors), to boost everyone’s understanding of airtightness and develop a spirit of collaboration. The sequence of work was reprogrammed to achieve a tested airtight shell, prior to proceeding with first and second fix.

The result was compliant and satisfying – 0.48, significantly below the requirement of 0.6, and a 95% improvement on UK building regulations.

Services strategy

The services strategy is developed to integrate centralised full mechanical ventilation with heat recovery (MVHR) for winter operation, combined with natural passive ventilation for summer day ventilation and night cooling. Heating is by means of simple thermostatically controlled radiators supplied by small gas boilers which provide controllable top up heat, although for most of the school day the heat of occupants reclaimed by the MVHR is sufficient to maintain comfortable temperatures.

Windows and doors

Particular attention was given to the design of windows and doors to balance the additional costs of the required 0.8 U-values, and achieve the required daylighting and levels of ventilation. We opted for a curtain walling system with simplified and optimised openings.

Primary energy

In contrast to UK regulations, PHPP takes into account all energy consumption including the unregulated (IT, other equipment and fittings). A key challenge has been addressing the energy consumption of the school’s kitchen, as most German schools do not have catering facilities. We opted for electric induction cooking, which is not only more efficient but significantly reduces the need for energy wasteful extract ventilation. The catering staff are delighted with the speed of induction cooking and the increased comfort and lower temperature of their new kitchens.

Conclusion

We’re delighted with what we’ve achieved at Oakmeadow. The layout works effectively for the functioning of the school, the teaching spaces are full of daylight and natural materials, the quality of air delivered by the ventilation system is excellent, and the heating consumption is on target at 15 kWh/m2/yr over the first year of operation – actually 90% less in the first year of operation compared to the old school building.

Selected project details

Clients: Wolverhampton City Council

Architects: Architype Ltd

Contractor: Thomas Vale Construction

QS: Smith Thomas Consult

Structural engineers: Price & Myers LLP

Services consultants: E3 Consulting Engineers LLP

Airtightness tester: HRS Services

Passive house consultants: Elemental Solutions

Passive house certification: Peter Warm

Timber frame: Cygnum

Windows & doors: Gutmann

Roof lights: Raico

Cellulose insulation: Warmcel, installed by PYC Insulation

Additional insulation: Permarock & Jablite

Airtightness products: Ecological Building Systems

Gypsum fibre boards: Fermacell

Ceiling tiles: Troldekt, supplied by Skanda Acoustics

Heat recovery ventilation: Swegon

Condensing boilers: Remeha

Additional info

Project overview: Building type: 2434 sq m new build 2 form entry primary school with additional multi agency support team area, all of timber frame construction

Location: Oak Meadow Primary School, Wolverhampton

Project budget: £4,977,800

Passive house certification: certified

Space heating demand: 15 kWh/m2/yr

Heat load: 12 W/m2

Primary heating demand: 113 kWh/m2/yr

Energy performance certificate (EPC): B - 35

Heating bills: not provided

Airtightness (at 50 Pascals): 0.48 ACH

Ground floor construction: 250mm high density Jablite insulation (installed in two staggered layers), 300mm power floated slab, floor finish. U-value: 0.064 W/m2K

External wall construction: 12.5mm Fermacell internally, followed outside by 38mm service void, 18mm OSB sealed with Pro Clima tapes, 140mm structural zone, 200mm duvet layer (both above zones fully filled with Warmcel blown recycled insulation), 18mm Bitroc sealed with Pro Clima tapes for airtightness, 50mm cavity, Douglas Fir cladding. Permarock system including DPM, render system and 200mm of EPS 200 insulation at sides of concrete slab U-value: 0.13 W/m2K

Pitched roof construction: ceiling, followed above by ceiling void, 15mm Fermacell (fire lining), 18mm OSB (airtightness, Pro Clima tapes), 400mm I joist fully filled with Warmcel, 9.2mm Panelvent, breather membrane, ventilation zone, 18mm plywood, membrane, aluminium standing seam. U-value: 0.10 W/m2K

Windows: triple-glazed, Gutmann Mira Therm08 passive house certified windows. U-value: 0.9 W/m2K

Doors: triple-glazed, Gutmann S70+ (not passive house certified)

Curtain walls/roof lights: Triple-glazed, Raico - Therm+H-i (Isoblock P gasket) passive house certified

Airtightness: Pro Clima airtightness sealing tapes between 18mm OSB and windows/ doors/curtain walls. Pro Clima wind tightness sealing tapes between 18mm Bitroc and windows/doors/curtain walls

Heating system: two Remeha quinta pro 65kw high efficiency condensing gas boilers.

Ventilation: Swegon Gold RX 25 and a Swegon Gold RX 12 AHUs complete with rotary heat exchanger

Green materials: All timber used throughout building within structure and Douglas Fir cladding is untreated (exception: some internal plywood finishes are treated for spread of flame), natural linoleum/rubber floors, Warmcel insulation, Keim mineral paints, Ecos organic paints and OSMO natural paints.