- Heating

- Posted

Geo Dynamics

The recent emergence of renewable energy heating systems has brought with it much discussion of the relative environmental and economic benefits of the different options. Heat pumps, which can require a substantial electrical input, have their advocates and detractors. Richard Douthwaite looks at the viability of heat pumps, and the factors that could determine their future role in a changing energy landscape.

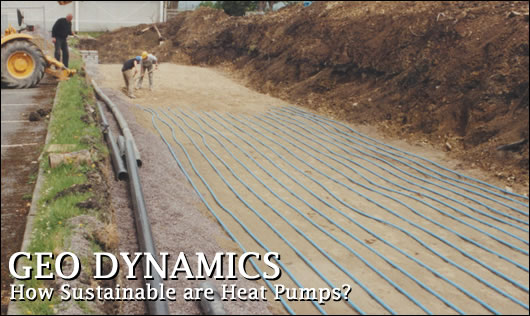

By the middle of February, Sustainable Energy Ireland had received 3,500 applications for grants from people wishing to install air- or ground-source heat pumps in their homes under the Greener Homes Scheme which was launched at the end of March last year. The grants available range from €4,000 for an air-source heat pump and €4,300 for a ground source pump using horizontal pipes, to €6,500 for one with vertically bored pipes. Consequently, if all these applications are approved and the installations go ahead, the public purse will pay out at least €15 million.

What will the public get for that subsidy? The Greener Homes Scheme is designed to encourage people to heat their homes with renewable energy but, since heat pumps are powered by electricity and only 5% of Irish electricity comes from renewable sources, should their installation really be grant-aided at all?

I began to ask myself that question when I came across a document on the website of a small German electricity company which concluded: “A ground-source heat pump can only be considered acceptable as an alternative to conventional heating systems from an environmental point of view if it has a coefficient of performance of over 4, gets its electricity from a CO2 free source and uses a climate-friendly refrigerant. As most current heat pumps do not meet these criteria, we advise against their use.”

I asked a friend to do a quick translation of the whole document because I knew a little about the company involved, Schonau Electricity Works, (EWS). EWS was set up ten years ago to take over the electricity grid in Schonau, a town with around 2,500 inhabitants in the Black Forest in Southern Germany, not far from the Swiss border. The driving force behind it is Ursula Sladek, the wife of a local GP, Michael, who, like 200 other townspeople, is also involved in the company. Since EWS does not own any generating capacity, its emphasis has consistently been on getting its customers to use less electricity rather than more!

“Heat pumps are subsidised by being given special electricity price tariffs” the article, which was written by Mrs. Sladek, says. “If, as one must suppose, power prices rise massively in the future, the economic viability of heat pumps will decline rapidly. What is more, heat pumps users are making themselves dependent on their power suppliers for the long-term”.

Let's look at these criticisms in more detail. A heat pump's coefficient of performance (COP) measures how much more heat it gives out than would be produced by using the electricity directly in, say, a conventional electric fire. If the COP is 3, for example, the pump delivers 3kWh of heat for every 1kWh of electricity it consumes. That seems straightforward, but, unfortunately, a pump's COP is not fixed. It varies according to the difference between the temperature at which the pump takes in heat from the outside world and the temperature at which it puts the heat out into the building. This difference is known as the 'thermodynamic lift'. “For any given lift, the actual incoming and outgoing temperatures don't make a lot of difference” says Paul Sikora of Dunstar, who supplied Table 1.

The number of kWh of heat a heat pump can put outfor each kWw of electricity it uses is largely determined by the difference between the temperature of its heat source and that of its output. In this chart, the temperature of the heat source is describee as the evaporating temperature, and the temperature of the output is called the condensing temperature. Thus, if the fluid in the underground coil of a ground source heat pump enters the pump at 10 deg C and the pump is putting hotter water into an underfloor heating system at 35 deg C, the chart shows that it should be giving 7.99 times more heat out than came from the electricity alone

Ground source heat pumps score over air-source ones because they have higher intake temperatures on exactly the days when heat is needed most. In Ireland, the ground is a constant 11 – 13°C several metres below the surface whatever the time of year, so the temperature of the mixture of water and antifreeze flowing into the heat exchanger on the heat pump can be quite high – perhaps 10°C if a long enough collecting pipe is used. However, if the outside air is the source of heat, a pump's performance in midwinter when temperatures fall below freezing on a cloudless, windless night can be very poor.

The line shows how the heat output of an air-source pump drops off sharply at around 6 deg. C

Derek Phelan of G.T. Phelan Ltd, which sells Toshiba air-to-air heat pumps, says that all air-source pumps are rated on the basis of a 7°C external air temperature and that there is a sharp fall off in efficiency when the external temperature falls below 6°C. As a result, by the time the outside temperature is down to zero, the pump will only give about 75% of its output. If the outside air drops as low as -15°C, the output is down to 45% .

Part of the reason for loss of efficiency is that, because of the high humidity in Ireland, ice forms on the cold metal surface of an air source pump's heat exchanger and prevents the energy that can still be found in the cold outer air passing through to warm the refrigerant within. To deal with this, air-source pumps have to have a defrost cycle to melt the ice and allow the heat exchanger to work properly. Naturally, providing this heat means that there is less available to warm the house. “At external temperatures of +5°C or below, the average defrost time is about 7 minutes per hour,” Phelan says, “but as the external temperature drops, its moisture content also falls and so the defrost, interestingly enough, becomes less of an issue.” So, while an air source pump can match the COP of a ground-source one if the external air temperature is 7°C or more (some Toshiba pumps have a COP of over 4) they have lower COPs than ground-source ones during periods of cold weather.

Since only 5% of Irish electricity comes from renewable sources such as the Arklow banks wind farm, the vast majority of heat pumps are currently reliant on fossil fuel generated electricity to operate

Among the other factors that affect a heat pump's efficiency are the type of refrigerant it uses, the operation of the refrigerant flow control unit, the type of heat exchanger and compressor used and their build quality. This makes it very difficult for buyers to know exactly what they are getting, particularly as there is no efficiency rating label as there would be if they were buying a refrigerator. Their only guide is the COP figure that manufacturers give in their literature but these are calculated using different thermodynamic lift benchmarks by different rating agencies and the brochures often fail to say what these were. One notable and prominent exception is the Eurovent independent rating system, which applies to many of the air source heat pumps on the market. The Eurovent website features independent rating results for a broad range of heat pump manufacturers, often encompassing their entire range of heat pumps. It is particularly difficult to compare COPs from air-source and ground-source machines because a ground source COP is usually based on a heat intake temperature of 0°C, a very low figure for Irish conditions, whereas the air-source intake is based on 7°C. “I'd very much like to see proper efficiency rating labels introduced” Phelan says.

Although Sikora says the choice of refrigerant can make a difference of up to 10% in a heat pump's efficiency, it was whether it was climate-friendly or not that concerned Mrs Sladek. Heat pumps manufactured some years ago used freons as a refrigerant. These were CFCs, chlorinated fluoro-carbons, which were found to be largely responsible for the destruction of the ozone layer and banned under the Montreal Protocol. This led the industry to switch to hydrofluorocarbons (HFCs) such as R-134A which has no ozone depletion potential and is what the industry describes as a “modest” global warming potential (GWP) of 1300. The GWP is an assessment of the effect the refrigerant will have on the climate in the next 100 years. CO2 has a GWP of 1 and can even be used as a refrigerant itself but the working pressures are very high. Propane, which needs a lower working pressure and has a GWP of 3, is gradually coming into use although it does present a fire risk.

Despite its “modest “ GWP, the use of HFCs worries Mrs. Sladek. She assumes that about 2% of the refrigerant will be lost in filling the heat pump, a further 3% every year during use, and then 13% at the end of 15 years when the unit is scrapped, giving total losses of 60%. This means that every heat pump has a climate effect equivalent to 1.2 tonnes of CO2 from the loss of its refrigerant on top of that due to its electricity use. Other people regard this extra tonnage as insignificant. According to Phelan, refrigerant loss should not be an issue. “Systems which are correctly installed and adhere to basic installation practices - which are now a requirement under EN 2078 - are pressure tested to ensure the integrity of the mechanical joints or welds on the pipework. Once this is achieved, the system is effectively a sealed system and no loss of refrigerant will occur.”

However if one looks at Table 2, it is clear that unless a heat pump does operate at a COP of 4 or more, its effect on slowing climate change is also going to be insignificant. As far as greenhouse emissions are concerned, one might as well use gas, or even oil, directly for one's heating. Only if the pump is used to replace the direct use of electricity for heating will carbon emissions fall.

To get the most from any heat pump, one needs to maximise the temperature at which it takes in heat and minimise that at which it goes out. It is very much better to use the hot water from a pump for an underfloor heating system (above) rather than in conventional radiators (below) because an underfloor system uses water at 35 deg C while radiators might operate at 60 deg C

A variable electricity tariff and smart meters will require heat pump users to store heat in some way. One of Ireland's heat pump pioneers, Bill Quigley, now of Nutech Renewables, developed such a system in the 1980s, at least twenty years ahead of his time. In those days, Quigley was manufacturing a house heating system called Trisol in which a heat pump took its energy from a solar collector and put it into a heat store for distribution when it was needed through hot air ducts. “We were a little bit slow on the uptake” Quigley says today, “but we eventually realised that the solar element was the best.” So this is where he is concentrating his efforts today.

However, the heat store he devised and supplied worked very well. It used sodium sulphate decahydrate (Na2SO4, 10H2O), better known as a laxative, Glauber's Salts. This is a phase change material which takes in energy when it melts and gives it out again when it solidifies. Water does the same when it turns to ice, but sodium sulphate changes phase at a much more convenient temperature for house heating purposes, 32°C. Google lists a lot of patented heat storage systems involving this property.

I've come to two conclusions about the SEI's grants for heat-pump installation. First, they are being paid on the wrong basis. Although it would be more difficult administratively, they should be paid on a sliding scale according to an installation's COP in actual use, with a cut-off below 3.5. This would give a boost to suppliers of the more efficient machines and force people to optimise their use. My second conclusion is that they should only be paid for installations which can be adapted later to cope with smart metering and intermittent supplies of electricity. One of the better reasons for giving grants is to get people to do things which will stand them, and the whole country, in good stead in the future but which the market is failing to signal that they should do now. Giving grants only for adaptable systems would over-ride the market's failure and get us to do the right thing today.

- douthwaite

- Geothermal

- heat pumps

- grants

- ground source

- underfloor heating

- geo

- Greener Homes

- fossil fuel

Related items

-

Grant integrated heating packages installed for 61 homes in Rathdrum

-

New scheme offers up to €75,000 retrofit loans at low cost

-

Offaly new build installs Grant integrated heating package

Offaly new build installs Grant integrated heating package -

Is it okay to retrofit heat pumps before building fabric?

-

Government supported almost 27,200 home energy upgrades through SEAI in 2022

-

Solar panels to receive VAT drop in aim to boost uptake

Solar panels to receive VAT drop in aim to boost uptake -

Hevac launches hot water heat pump with green refrigerant

Hevac launches hot water heat pump with green refrigerant -

Viessmann launch two new compact heat pumps

Viessmann launch two new compact heat pumps -

Mitsubishi heat pumps 6-7 times lower CO2 than condensing gas boilers

Mitsubishi heat pumps 6-7 times lower CO2 than condensing gas boilers -

Huge demand for new deep retrofit grants

-

Major new grants for retrofit & insulation announced

Major new grants for retrofit & insulation announced -

Daikin launches new Altherma 3 R heat pumps

Daikin launches new Altherma 3 R heat pumps