Harp attack

The HARP database allows Building Energy Rating assessors to enter real performance data for heating appliances when calculating Building Energy Ratings rather than low default scores - but few renewable appliances are listed, and the industry appears confused and deterred by the application process. Lenny Antonelli investigates.

Listing the estimated seasonal efficiencies of technologies including gas, oil and biomass boilers, solar thermal panels, heat pumps and CHP units, HARP (Home-heating appliance register of performance) is Sustainable Energy Ireland's database of household heating appliances. If an appliance is listed on HARP, its certified performance figures can be used when calculating Building Energy Ratings rather than conservative default values, which often drive ratings down.

Clearly it's in the interest of manufacturers and suppliers to have their appliances listed - doing so makes BER-conscious builders and architects more likely to specify them over unlisted appliances for which low default scores must be entered. But at the time of going to print, there were just three heat pumps, ten solid fuel boilers (including seven pellet and two log boilers) and thirteen solar panels on HARP compared to 3,043 gas, oil and LPG boilers. Speaking to Construct Ireland, various industry figures said the requirements for getting listed are impractical and overly stringent, while there also appears to be confusion regarding SEI's application requirements.

SEI told Construct Ireland that HARP applicants must submit certified test performance data that has been accepted by an accredited body along with an application form and photographs of the appliance. This seems straightforward, but various industry figures said that in practice getting listed is difficult.

"I recall spending quite a bit of time trying to go through the form and it was extremely tedious, and in the end I decided the day was too short to get through the procedures," said Paul Sikora, former MD of the now defunct Irish heat pump manufacturer Dunstar.

High standards are clearly important, and some form of independent

certification is necessary if performance data is to be used when

calculating BERs. However, with so few renewable appliances on HARP,

it's obvious sections of the industry aren't engaging - or are

struggling to engage - with the application process.

The requirements for getting listed are essentially the same for gas

and oil boilers as for other appliances, but many models in this

category were automatically transferred to HARP from SEDBUK, the UK's

boiler efficiency database.

The HARP database is administered by Gastec, the UK company that also

processes applications for SEDBUK. Construct Ireland contacted Gastec,

but the company directed questions to SEI. One industry figure told

Construct Ireland that in his experience, SEI were generally willing to

accept performance data and certification provided Gastec did.

With the actual efficiency figures of many common gas and oil boilers

readily available to BER assessors - and the seasonal efficiencies of

many renewables not - there's a danger the market for these

technologies could be depressed as builders and architects look to

boost BERs by selecting HARP-listed oil and gas appliances instead.

One story relayed to Construct Ireland by Mike Teahan of heat pump

supplier HSB demonstrates this. Teahan said that a developer his

company supplied 5kW heat pumps to for a mid-sized residential

development almost opted for gas boilers instead, as HSB was unable to

get the unit's performance data accepted based on certified results for

the equivalent 8kW device. Ultimately the BRE - the UK's Building

Research Establishment - were engaged to separately certify the 5kW

machine. Various industry figures that Construct Ireland spoke to said

that, in a line of heat pumps that are essentially the same apart from

the size, the difference in COP is unlikely to vary by more than 0.1.

So what are the main difficulties regarding HARP within the industry?

Speaking to Construct Ireland, industry figures said SEI's application

requirements make it difficult for appliances to be self-certified by

manufacturers. Self-certification enables manufacturers to test the

performance of their own appliances, and can be an effective way of

enabling the industry to demonstrate the efficiency of its products

without imposing excess cost and administration - provided the process

is independently audited and monitored to verify results.

The HARP database lists over 3,000 gas, oil and LPG boilers, many of them transferred from SEDBUK, the UK's database of boiler efficiency. However, just three heat pumps are listed. Various industry figures that Construct Ireland spoke to said the application requirements were impractical and overly stringent

Responding in writing to questions from Construct Ireland, SEI said: "Self-certification is acceptable where a notified body has confirmed that the test results are valid and generated according to the appropriate standards. For example, a notified body may be in a position to accept a manufacturer’s 'self-certification laboratory' as providing correct test results to the appropriate standard... Regarding 'self-certification', this has a very specific meaning under legislation (i.e. 'Manufacturer declared values'). In order for a manufacturer to self-certify an appliance, they must test in accordance with the appropriate standard in an appropriate facility and there must be oversight to the testing procedures and declared results... Self-certification in this form is a long established mechanism for product certification."

By "notified bodies", SEI simply means laboratories accredited to the relevant European standard (EN17025 - general requirements for the competence of calibration and testing laboratories) that use appropriate European testing procedures (EN14511-2 for heat pumps, EN303-5 for solid fuel boilers, EN12975-2 for solar thermal panels, and the boiler efficiency directive for gas and oil boilers.) Speaking to Construct Ireland, Peter Murphy of heat pump supplier Glen Dimplex said SEI's procedure for self-certification is impractical. "When you drill down behind the practicalities it's unworkable. When you start looking at the conditions and all the paper work and auditing it becomes unwieldy. It's very bureaucratic and unwieldy to do it in practice."

"Most companies do some self-regulation,” Murphy continued. “They do testing, they have results on file, they can be audited and checked...There's a much more practical way of addressing the issue of quality and control in the sector, and that's self-certification. Other countries have embraced and developed it, why not follow their example? And it terms of how they've done things it's cheaper, faster and effective - and it will help them achieve their goal in terms of developing the sector."

Murphy stressed that he strongly supports high standards - he just wants meeting them to be practical for the industry. "I'm not suggesting anybody can self-certify. We agree with proper certification. We believe there should be standards and proper certification to prevent poor standards being adopted in the industry, but it's about striking a balance."

Many industry figures Construct Ireland spoke to said SEI's requirements make it difficult for a 'family' of products - a line of similar appliances that differ only by size or external appearance - to be HARP-listed based on the testing of one or two appliances in the line.

However, there would appear to some confusion in the industry on this matter. Various industry figures told Construct Ireland that, as far as they understand, SEI is demanding individual test data for each appliance.

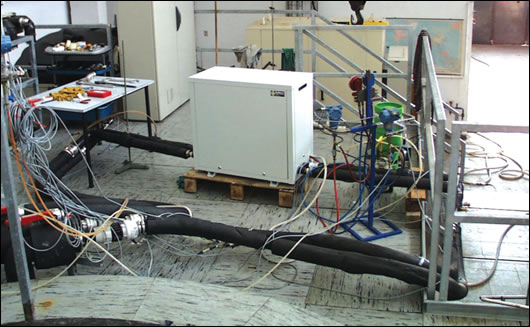

Techbase in Vienna, the headquarters of prominent test house Arsenal Research. Heat pump suppliers told Construct Ireland that Arsenal will certify the performance of a range of heat pumps based on testing a sample of the range

In their email to Construct Ireland, SEI outlined their approach to

allowing families of products to be certified: "Test results can apply

to a range of products provided a notified body specifically states

which products the test results apply to. For example, if a

manufacturer has several products in the same 'family' then these can

share common results provided that the notified body stands over a set

of results for that family."

Essentially this means a recognised test centre would need to verify

the performance of a line of appliances based on testing a sample of

the range. However, speaking to Construct Ireland, Reginald Brown of UK

test house BSRIA said he didn't think it was common for test centres to

take this approach with heat pumps, but that it could be more

appropriate for boiler testing. One heat pump supplier Construct

Ireland spoke to said his company would be approaching their test

centre to see if they were amenable to this approach.

Peter Murphy, Glen Dimplex's manager of new technologies &

renewables, told Construct Ireland he didn't think test houses would

certify the performance of one heat pump based on the results of others

in the same range. Murphy said it was only practical for manufacturers

to have their appliances individually tested if self-certification was

workable, and said he favoured a system whereby manufacturers test each

of their own products but are audited and certified by an independent

test house. He said that Glen Dimplex have over 100 product SKUs, and

that it would typically cost e8,000 to have each tested - plus the

expense of administration and travel.

While SEI told Construct Ireland they are happy to accept "common

results" for a family of products provided a notified body stands by

the results, there are clearly doubts as to how practical a solution

this is. Various industry figures told Construct Ireland that, as far

as they understood the rules, SEI are looking for appliances to be

individually certified. Some said they thought SEI's interpretation of

the rules had been relaxing recently.

"It's a nightmare," one supplier stated. "SEI have been looking to have

every single model tested, and that's an unreasonable request."

Gerry Duffy of Eurotech, the Irish supplier of Ochsner heat pumps, told

Construct Ireland he was initially being asked for test results for

every machine. Duffy said Ochsner is now applying for HARP-listing for

its extensive range of heat pumps based on testing and certification at

the Arsenal Research test laboratory in Austria. According to Duffy,

Arsenal will certify the performance of a range of heat pumps based on

testing a sample of the range - provided they have the opportunity to

initially select sample units from the full range.

A Dunstar heat pump undergoing testing at Arsenal in 2004

Dunstar heat pumps were also tested by Arsenal, Paul Sikora told Construct Ireland. "It involved testing a max of two or three of a line that could run to 10 or 12. Arsenal would select the models they wanted tested from the line and if those passed you would get blanket certification to say all the others were made to the same standard and equipped with the same basic characteristics."

He continued: "If you have a machine tested at the high and the low end, I think there's a fair amount of confidence that if both pass the performance bar, the stuff in between should be given benefit of the doubt. Anyone producing [heat pumps] in volume is going to look for a single range of compressors, expansion valves and all the stuff that has a bearing on the performance of the equipment."

In their response to Construct Ireland, SEI said: "It has always been our policy that if a notified body clearly stated that results applied to multiple products within a family then this is acceptable. However, if the supplier/manufacturer claims that the results should apply to a range of products in a family, then this is not enough."

Various indiviuals Construct Ireland spoke to also questioned whether the testing temperature specified in EN14511 - the testing standard for heat pumps - are suitable for calculating an accurate COP for Irish climatic conditions.

With regards to HARP listing, the situation for biomass boilers appears somewhat similar. Colm Byrne of renewables specialists Glas - suppliers of the Palazzetti range of wood heating appliances - told Construct Ireland that Palazzetti were being asked to provide separate certification for boilers that are mechanically the same, but have different exterior design.

"You have to have certification for everything in a range. Within the Palazzetti range there's about seven or eight stoves with a back boiler... there's one range where there's three identical boilers that just have different cladding. Effectively they're the same stove under a different name." The issue doesn't appear to be as pertinent to the solar thermal industry - probably because solar companies generally supply more or less panels depending on the size of the installation required - rather than offering a large range of different-sized panels.

However, it should be noted that SEI's application process does make an allowance for "badged" appliances - appliances that are the same "in all material respects" but that are sold under a different name. Warren Brown of biomass heating specialists Darionti told Construct Ireland in his experience, it was common for test facilities to base their performance data for a range of boilers on a sample from the range.

One approach to testing 'lines' of appliances recommended by various heat pump suppliers Construct Ireland spoke to is that taken by the European Heat Pump Association. The association awards a quality label (EHPA-DACH), and manufacturers applying for the label are allowed to divide heat pumps into "model ranges" - essentially a line of heat pumps that share the same key components - with a sample of appliances being tested but the full range being awarded the label. However, one heat pump supplier Construct Ireland spoke to said SEI did not accept this label.

Peter Murphy of Glen Dimplex said that while he supports high standards in heat pump certification, meeting them needs to be practical for the industry

Various industry figures also expressed concern that the current rules require them to completely re-test their appliances when any modifications are made, as well as whenever a new product is launched. Others pointed out that the waiting times for testing at many prominent test facilities can amount to years rather than months.

While SEI do have certain allowances for self-certification and the certification of 'families', and are right to insist on independent oversight and high standards, the low numbers of successful applications to HARP makes it clear the industry is not engaging. Paul Schweppe of Core Air Conditioning - suppliers of Carrier heat pump systems - questioned whether large multinational manufacturers would be willing to spend much time trying to satisfy any requirements that are unique to Ireland, given the size of the market.

"We're defininitely open to discussions," Brian Motherway, SEI's head of industry programmes told Construct Ireland. "This is an evolving process. Every second conversation I have is saying that standards are too stringent or that standards are too lax. It's a difficult balance between protecting the consumer and allowing the industry to develop. The point of our interventions are to raise the market standards. Given that it's an evolving process we're happy to talk to the industry."

- Articles

- Energy Performance of Buildings Directive

- Harp attack

- building energy ratings

- HARP database

- Home-heating appliance register of performance

- solar panels

- heat pumps

- chp

- sustainable energy ireland

Related items

-

Grant integrated heating packages installed for 61 homes in Rathdrum

-

Embodied carbon & zero emission targets adopted in new EPBD

Embodied carbon & zero emission targets adopted in new EPBD -

Offaly new build installs Grant integrated heating package

Offaly new build installs Grant integrated heating package -

Is it okay to retrofit heat pumps before building fabric?

-

Solar panels to receive VAT drop in aim to boost uptake

Solar panels to receive VAT drop in aim to boost uptake -

EU votes through EPBD recast

-

Hevac launches hot water heat pump with green refrigerant

Hevac launches hot water heat pump with green refrigerant -

Viessmann launch two new compact heat pumps

Viessmann launch two new compact heat pumps -

Mitsubishi heat pumps 6-7 times lower CO2 than condensing gas boilers

Mitsubishi heat pumps 6-7 times lower CO2 than condensing gas boilers -

Major new grants for retrofit & insulation announced

Major new grants for retrofit & insulation announced -

Daikin launches new Altherma 3 R heat pumps

Daikin launches new Altherma 3 R heat pumps -

Waterford Stanley launch monobloc heat pumps

Waterford Stanley launch monobloc heat pumps