- Case Studies

- Posted

Healthy cottage upgraded

In 2005 Construct Ireland profiled the timber frame extension to Hannah and Martin Naughton’s Meath cottage. Five years later we’re returning to profile the upgrade of the original bungalow — a renovation that demonstrates how to detail dry lining without running the risk of mould growth.

Internal insulation has become a hotly debated topic in the last couple of years, partly because of Joseph’s Little’s ‘Breaking the Mould’ series of articles in Construct Ireland, which detailed potential condensation risks when insulating internally to onerous U-values. But now a project that’s almost five years old could demonstrate a suitably robust approach to dry lining – by carefully assessing condensation risk and not putting U-values before occupant health.

Hannah and Martin Naughton purchased their home in Slane, Co Meath in 1999, and Construct Ireland first featured the building in 2005. Writing in the magazine at the time, Hannah said: “From the day of the first viewing we knew that we wanted to extend and renovate the building, to create additional living space and improve the standard of the living.”

At the time she wrote the article the extension was just complete, but the Naughtons were yet to renovate the original cottage. Riverview Timber Frame built the 140 square metre timber frame extension, which they insulated with Holzflex woodfibre insulation, supplied by Ecological Building Systems. Riverview also used the Athboy-based company’s Intello airtightness tapes and DB+ cellulose intelligent membrane throughout the build.

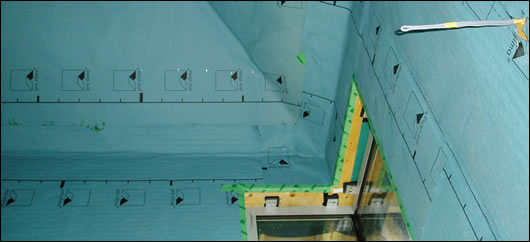

The Intello Plus membrane and Homatherm Holzflex woodfibre insulation supplied by Ecological Building Systems

Construct Ireland got back in touch with Hannah recently, and she told us that shortly after the extension was finished the couple started renovating the original 42 square metre cottage, insulating the walls and roof and installing new windows. Floors throughout were also insulated, with 70mm of rigid Kingspan board.

The Naughtons did most of the labour themselves. First Martin completely gutted the old cottage before removing the gypsum plaster from the original walls and then re-plastering. Niall Crosson, an engineer with Ecological Building Systems, says it was crucial to re-plaster the walls — gypsum is very prone to mould and deterioration if exposed to high humidities for prolonged periods and otherwise, there could have been gaps between the new internal insulation and the wall, cool spots which would be ideal places for condensation to form.

The Naughtons considered external insulation, but Hannah says that their stone walls are already very thick — external insulation would have made them even thicker, and she was worried this would mean less natural light getting inside. They opted for dry lining instead.

Martin studded the walls internally and the couple put 60mm of Holzflex woodfibre insulation between the studs. “By increasing the U-value to too high [a level] it may have introduced a greater interstitial condensation risk,” Crosson says, explaining why a only a modest amount of insulation was used on the walls.

The Intello Plus membrane and Homatherm Holzflex woodfibre insulation supplied by Ecological Building Systems

According to his calculations, the insulation improved the U-value of the walls from 2.22 W/m2K to 0.55 W/m2K. “While this isn’t groundbreaking, it is a substantial improvement compared to the original structure without introducing a condensation risk," he says.

Crosson analysed the proposed wall build-up with Wufi, the condensation analysis software, and was concerned that insulating to a better a U-value could lead to an interstitial condensation risk. This can occur if the temperature increase from the outside to the inside of the wall is too radical, which can potentially cause water vapour to condense, prolonged high humidity and a risk of mould.

Based on his Wufi calculation, Crosson also recommended that the Naughtons use a Pro Clima Intello Plus membrane on the inside of the insulation rather than Pro Clima DB+.

“DB+ was the very first intelligent membrane and it’s more commonly used in Germany where they’re more accustomed to working with paper-based membranes,” Crosson says. But he explains that Intello Plus offers greater protection than DB+, with a much greater vapour resistance in winter and slightly higher vapour openness in summer. He says this was necessary in the "more extreme environment” just inside the walls, which demanded a higher performance membrane for maximum security. “There are some cases, such as the thermal refurbishment of the inside of single leaf walls, where that higher performance is required.”

(left to right) the existing cottage in 2004 before the extension was built; the completed extension with work underway on the cottage renovation in 2008; and the finished project earlier this year

Unlike standard vapour checks or vapour barriers, Crosson says intelligent membranes have variable vapour permeability: in winter, their high diffusion resistance provides protection for the building’s structure, while in summer the low diffusion resistance facilitates rapid drying out of any moisture which may enter the building structure.

The Naughtons installed 300mm of Holzflex in the attic too, with a Pro Clima DB+ membrane taped and sealed over this. Crosson explains why DB+ was suitable for the attic: “Provided it’s taped and sealed with Pro Clima [products] there’s a very low risk of condensation as the attic has sufficient air movement to offset any risk of condensation, unlike the solid wall.”

Hanna Naughton’s a big fan of Holzflex. “It’s brilliant stuff to work with,” she says. While she originally budgeted less for insulation, she said spending more on Holzflex “was one of the best decisions” she made throughout the renovation, along with installing timber windows.

Supplied by Ecological Buildings System, Holzflex is a semi-rigid woodfibre insulation mat that’s designed to be flexible enough to fit between rafters, joists and studs. Manufactured by German company Homatherm, Holzflex is principally produced from wood chip. It has a thermal conductivity of 0.38 W/mK, and a density of 55kg per cubic metre.

Heat is distributed throughout the house by Zehnder steel radiators that run below 40C

“It’s a hygrothermal product,” Crosson says. “It can absorb a higher proportion of moisture before condensation arises, and without effecting thermal performance. It can help prevent timbers within the structure from being exposed to moisture. Coupled with its outstanding acoustic properties and high thermal mass, it’s conducive to a durable, healthy structure and a comfortable living environment.”

Hannah was particularly impressed by Holzflex’s fire resistance. In her 2005 article, she wrote about performing a fire test on various insulation products with Crosson. She wrote that Holzflex “did not even get hot with the gas burner. There was no flame, no smoke and just a bit of black surface afterwards. This was another impressive confirmation for us that we made the right decision.”

The Naughtons installed the Holzflex insulation throughout the house themselves — to save money, of course, but they had another reason too. “We said if we put all that money in we need to make sure it’s done properly.” Hannah says they stuffed Holzflex into “every little corner” they could.

The Naughtons opted for the same windows in the cottage as the timber frame extension — timber windows from Danish manufacturer Rationel Vinduer Ltd with an overall U-value of 1.1 W/m2K. The timber is northern European pine, and Rationel says it has a policy of systematically planting more trees than those felled for production. The company also says it recycles spare and broken glass, and that waste timber is used to fuel their factory’s CHP plant.

The cottage — home to Hannah’s office as well as a guest bedroom and bathroom — is heated by the same Weissmann high efficiency condensing gas boiler that serves the extension. The Naughtons were keen on a condensing boiler because of the efficiency gains they offer by capturing warm outgoing air to heat up cooler water coming back to the boiler from radiators. Hot water in the house is stored in a pressurised Tribune 210 litre cylinder, and heat is distributed throughout by what Hannah calls u “chunky” Zehnder steel radiators that run at a water temperature below 40C. The house has two manifolds, while each radiator has a separate connection to the manifold and a separate thermostat for individual control.

“Each thermostat sucks as much warm water from the manifold as it needs to bring the radiator up to the set level of heat and then sends the cold water back,” wrote Hannah in her 2005 article. When the Naughtons light their wood burning stove, it tends to shut the radiators down by heating indoor space to the required temperature.

The timber frame extension was insulated with Holzflex woodfibre insulation, cut to fit neatly into the timber studs

“Our heating system is oversized because we did so much in terms of insulation,” Hannah says. But she says that’s not such a problem, as the big radiators can take low temperature water, and each rad can be regulated separately.

In 2005 Hannah wrote of the cottage: “We loved the cottage but we always had cold feet from living in it. Our little babies suffered from snotty noses throughout the winter. Drafts made it rather uncomfortable to sit anywhere away from the open fire in the evening. And besides the fact that the radiators were hardly up to heating the house, we never had enough hot water and by far not enough of it, as the hot water and the radiators were on the same heating cycle.”

Pro Clima DB+ membrane

And now? “It’s a huge improvement, it’s very comfortable in the cottage,” Hannah says. “In the cottage, we have good heat retention, but we do feel the difference [compared to the extension]. We feel when we walk over to the cottage there’s a real drop in temperature.”

“Naturally I’m feeling colder so I have to switch on the radiator in the office,” Hannah says. She says the cottage warms up nicely in the morning as it’s hit by the sun, but that it doesn’t get much sun in the afternoon or evening because of overshadowing by the extension. But she adds there’s “no draughts, no cold feet. It’s very comfortable.”

The Naughton’s cottage isn’t the most energy efficient upgrade we’ve featured in Construct Ireland — but that’s not the point. It’s clear there’s growing concern at the potential risk of interstitial condensation when insulating walls internally to better and better U-values, and as energy upgrade work expands nationally, we urgently need examples of internal insulation projects in which issues surrounding condensation are thoroughly considered. The Naughton’s renovation might not be the most ambitious we’ve ever featured, but it might just represent best practice in internal dry-lining insulation.

Selected project details

Clients: Hannah & Martin Naughton

Wood-fibre insulation and airtight system: Ecological Building Systems

Timber frame extension & outhouse: Riverview timber frame

Windows: Rationel

Floor insulation: Kingspan

Radiators: Zehnder

- Articles

- Case Studies

- Healthy cottage upgrade

- timber frame

- dry lining

- mould growth

- Holzflex

- Woodfibre Insulation

- insulation

- airtightness

Related items

-

Air tightness training course to launch in Carlow this March

-

Peaky blinder

Peaky blinder -

New Ejot profile cuts thermal bridging losses by 25mm insulation equivalent

New Ejot profile cuts thermal bridging losses by 25mm insulation equivalent -

Why airtightness, moisture and ventilation matter for passive house

Why airtightness, moisture and ventilation matter for passive house -

Airtight delight

Airtight delight -

Ireland’s first 3D printed homes insulated with clay foam

Ireland’s first 3D printed homes insulated with clay foam -

Unilin Ireland launches embodied carbon report

Unilin Ireland launches embodied carbon report -

Up to 11

Up to 11 -

It's a lovely house to live in now

It's a lovely house to live in now -

Ecological launches Retro EcoWall for internal wall insulation

Ecological launches Retro EcoWall for internal wall insulation -

We Build Eco flat pack timber frame partnership gathers pace

We Build Eco flat pack timber frame partnership gathers pace -

Partel’s airtight membranes now certified for passive house construction

Partel’s airtight membranes now certified for passive house construction