- Product News

- Posted

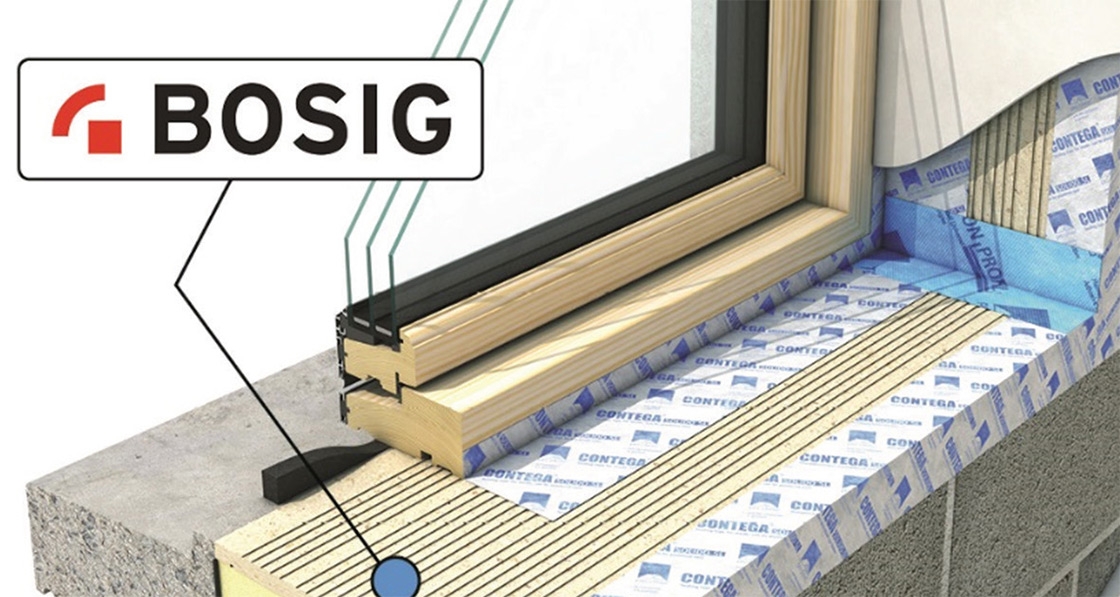

Ecological launches thermal bridging solution

With increased requirements to address thermal bridging at critical junctions such as windows, doors & foundation, Phonotherm 200 offers homeowners, builders and specifiers a robust, practical and effective thermal solution.

Niall Crosson, senior engineer with Ecological, said: “It is well known that thermal bridging has a negative impact on the thermal resistance of building elements, along with the additional risk of condensation and mould growth, and the resultant deterioration in indoor air quality.

Ecological are delighted to supply a solution to address thermal bridging at key junctions which is not only effective, but also more ecological compared to alternative materials as it is sourced from a raw material which would otherwise go to landfill.”

Ecological will also supply complete thermal bridging analysis and support to designers and specifiers from their technical department, to complement their existing hygrothermal, U-value and dew point assessment service.

Phonotherm 200 is primarily utilised for applications where structural support and the possibility of obtaining secure fixings into the material are required. Phonotherm 200 is 100% water resistant, diffusion open, easy to machine with conventional carbide tools, and effectively reduces thermal bridging at critical junctions.